Engine

The original manual prescribed SAE 10W-30 / API SC or SD motor oil. Today such oils are only produced for classic cars and, generally, there is no point in using these in the Volga engine – more modern oils which are still widely available on the market work just as well, or better. However, the newest, most modern types of motor oil, which are specifically designed for the needs of modern engines, are best avoided as well.

Use SAE 10W-30, 10W-40, 15W-30 or 15W-40 / API SF, SG, SH or SJ motor oil. Oils with lower ash content (<1 %) are to be preferred.

Worn-out engines may need SAE 40 or even 50 viscosity grade oils to compensate for the wear of the crankshaft journals and bearings, that would keep the oil pressure steady and may somewhat reduce oil consumption (blue smoke from the exhaust).

Change oil at least every 5 000 kms (the manual recommends oil change interval of no more than 10 000 kms for “light driving conditions”, which basically do not exist anymore, anywhere – any modern driving conditions should be considered “severe”, and the interval should be reduced).

The Volga engine is not designed for modern motor oils, especially the earlier modifications (produced before late 1970s) with a road draft tube for crankcase ventilation, which doesn’t work while the car is not moving and is inefficient at high engine revolutions, thus allowing significant oil oxidation. Together with the less efficient piston rings design and other factors, this may lead to abnormal exhaustion of additives in the oil, which in turn may cause formation of deposits in the engine.

Most modern oils, especially diesel oils, have high additive content, which in older engines may lead to rapid sludge & deposit build-up and increased engine wear (hence the recommendation to use oils with lower ash content, which usually translates as “lower additive content”). Fully synthetic oil is known to cause leakages, its use requires a complete replacement of all oil seals and gaskets (use FPM / Viton oil seals and silicone gaskets, if possible).

The Volga engine also does not need the additional protection provided by modern engine oils because it is a low-revving, under-stressed engine designed to run happily on the oils available in the USSR back in the 1960s (API SC & SD analogs, often worse than that in practice).

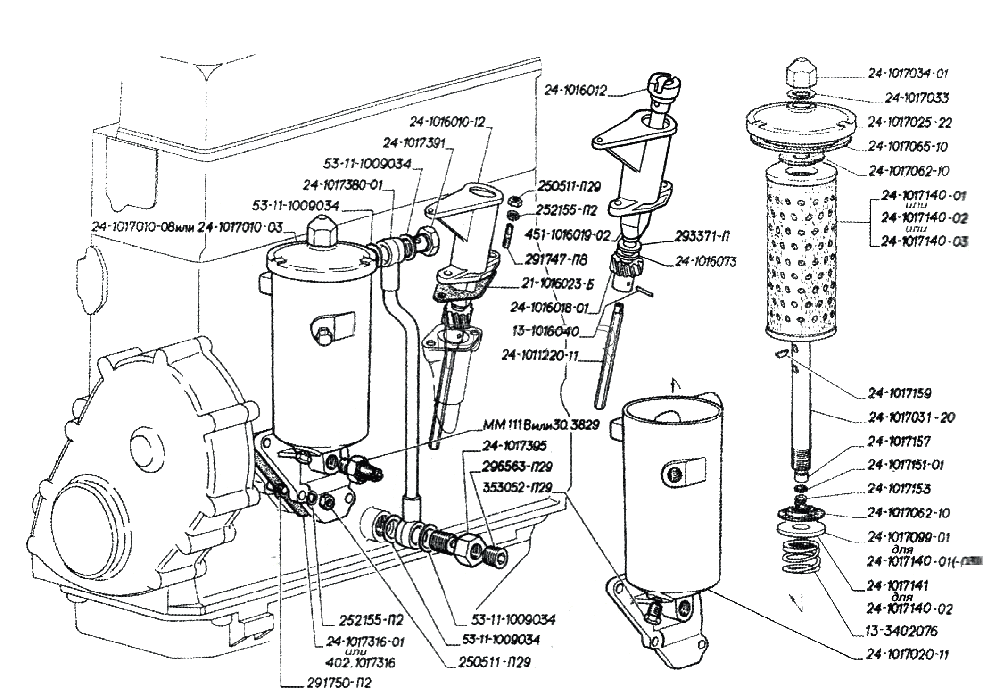

The full-flow oil filter is of the type with a permanent housing and a replaceable filter element, much like in some modern German cars. 24-1017140 filter element is still produced and available in the former USSR countries. Can be substituted with Mann H727/4 and analogs (higher quality, work better with modern oils).

Two 24-1017062 rubber gaskets may need to be replaced together with the filter if the original ones have disintegrated over time, as well as the 24-1017065 filter cap gasket ring (both parts are available worldwide from classic car parts dealers, such as Retrodetal).

Don’t forget to soak the filter element in oil before installing and drain the sludge by unscrewing the drain plug located on the lower portion of the filter housing. As an alternative, adapters for modern, spin-on style oil filters exist, they are available via classic car parts dealers in Russia.

The Volga engine uses a rope-type rear main crankshaft oil seal. Modern motor oils, especially synthetic, may cause oil leakage in engines with old, worn-out seals, but a recently replaced one should work just fine, if the job was done right. A known replacement part available worldwide is Mercedes-Benz A0019971241 Crankshaft Oil Seal (needs to be slightly shortened, but overall fits just fine). Front crankshaft seal is of the ordinary type (p/n 21-1005032-01; can be substituted with Victor Reinz 80-36978-00 or analog).

Transmission

Use SAE 75W-80, 80W-85 or 80W-90 / API GL-3 (originally specified by the manufacturer) or GL-4 (widely available modern analog) transmission oil in the gearbox and API GL-5 / Hypoid transmission oil in the rear axle.

DO NOT use GL-5 oil in the gearbox, this may cause hard, noisy shifting and premature wear of the synchromesh.

Thicker (SAE 140 viscosity grade) oil is known to reduce the howling of a worn rear axle.

Steering box

Same as gearbox (GL-5 transmission oil also can be used).

Hydraulic systems

Before 1985, hydraulic braking systems and clutch linkages of all Volga cars were filled at the factory with Castor oil / butyl alcohol based crimson brake fluid named BSK (DOT-2 analog). It is not interchangeable with, nor can be mixed with, any other types of brake fluids.

This type of brake fluid was developed in mid-1950s and used in USSR/Russia well into 1980s and even 1990s. It was actually good for what it was designed for, namely – braking systems with drum brakes and a low level of heat generation. It is no longer in production because it cannot be used in cars with disk brakes due to its relatively low boiling temperature, and in fact it is more expensive to produce than modern synthetic break fluid (some manufacturers produce BSK “analogs”, but these products are in fact cheap glycol based brake fluids and are not compatible with the original Castor oil-based BSK, or the type of rubber originally used in the Volga brakes; don’t use this surrogate stuff).

Another problem is that – if enough alcohol, which is used in this type of break fluid mostly as a preservative, escapes the system through evaporation, the castor oil would eventually rot and turn into disgusting jelly, ceasing to function as a hydraulic fluid and clogging up the braking system completely. This usually happens if the car was unused for a long time and fresh break fluid or alcohol were not added to compensate for evaporation. The only proper course of action in this case is a compete overhaul of the entire system.

Warning: the type of rubber that was originally used for the hydraulic seals in these cars is not compatible with glycol based brake fluids.

DO NOT use any other type of brake fluid unless all and every rubber part in the system is replaced with a brand new one ! DO NOT mix Castor oil based and Glycol based brake fluids ! In both cases the hydraulic braking system would be rendered inoperative (either instantly or in some time) because the rubber would turn into goo.

Mineral oil based brake fluids are also quite lethal for the rubber used in these systems.

If the level of fluid in the brake or clutch master cylinder reservoir filled with crimson brake fluid drops, as a “roadside fix” you can top it up with pure castor oil (available via drugstores / pharmacy stores), that would lower its boiling point a bit, but the brakes will continue functioning properly. Butyl alcohol (butanol) is also good for this purpose (but somewhat harder to get). Ethyl alcohol (ethanol) can be used as well, but it evaporates relatively quickly, causing the level of the fluid to drop, and also has a lower boiling temperature than butanol.

The applicability of silicone-based brake fluid (DOT-5) is still in question, some owners have experienced compatibility issues with such fluids.

GAZ-3102 (front disk brakes), GAZ-24-10 (either disk or drum brakes) and other later Volga models use standard Glycol-based DOT-3 & 4 compatible brake fluid.

Note: some of the cars may already have been converted to DOT-3/4 brake fluid – check the brake master cylinder and clutch actuator reservoirs for what type of fluid they are filled up with. Castor oil based brake fluid is crimson to orange and has a very specific odor; DOT-3/4 is transparent or yellowish (tends to become black over time because of tiny particles of rubber and metal dust floating in it) and almost has no smell. BSK does not mix with water (they will separate into layers), while DOT 3/4 will mix with water in any proportion. It is not uncommon that even in the same car the clutch linkage and the hydraulic braking system are filled with different types of fluid.

While rebuilding the brakes, always use castor oil / glycol based brake cylinder assembly paste (Rubber Grease) to lubricate cylinder bores, pistons and all rubber seals.

Chassis lubrication

Use any light transmission oil.

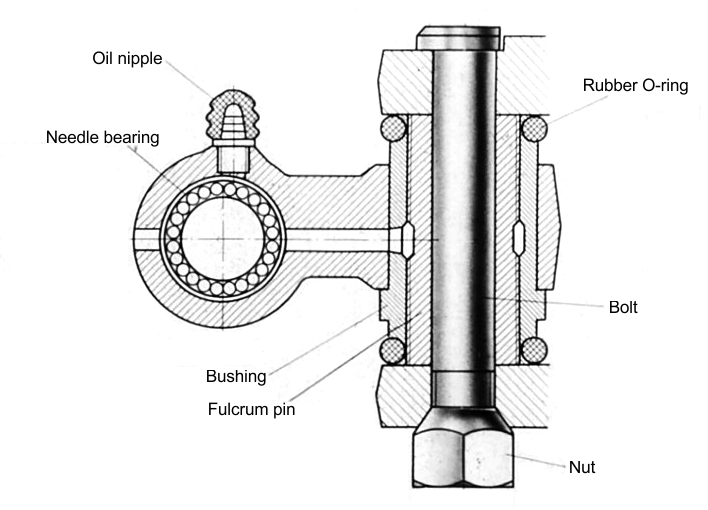

GAZ-24 Volga, unlike many cars with kingpin type suspension, has its kingpins rotating in needle roller bearings, not bronze bushings, and these bearings should be lubricated with light oil only (SAE 50 weight engine oil or transmission oil).

DO NOT use any kind of thick grease for this purpose, as it tends to clog up the lubrication channels drilled in the suspension upright, and you’ll eventually have to disassemble the whole unit for cleaning because the grease will just stop getting to the joints.

The lower trunnion is especially susceptible to this because it is lubed through the same oil nipple as the lower kingpin bearing, and therefore the grease has to pass at first through the bearing itself, and then through a long and narrow channel drilled in the steering knuckle support, which is prone to clogging. Adding a separate oil nipple for the lower trunnion is a known good solution to this problem.

It may be possible to substitute light oil with the type of lubricants used in centralized lubrication systems on trucks / trailers / buses (NLGI 000 grade greases, very light consistency, almost like thick oil), but use it at your own risk (such greases are usually made using too low viscosity base oil; base oil viscosity of the grease should be no less than 100…150 cSt, or preferably higher).

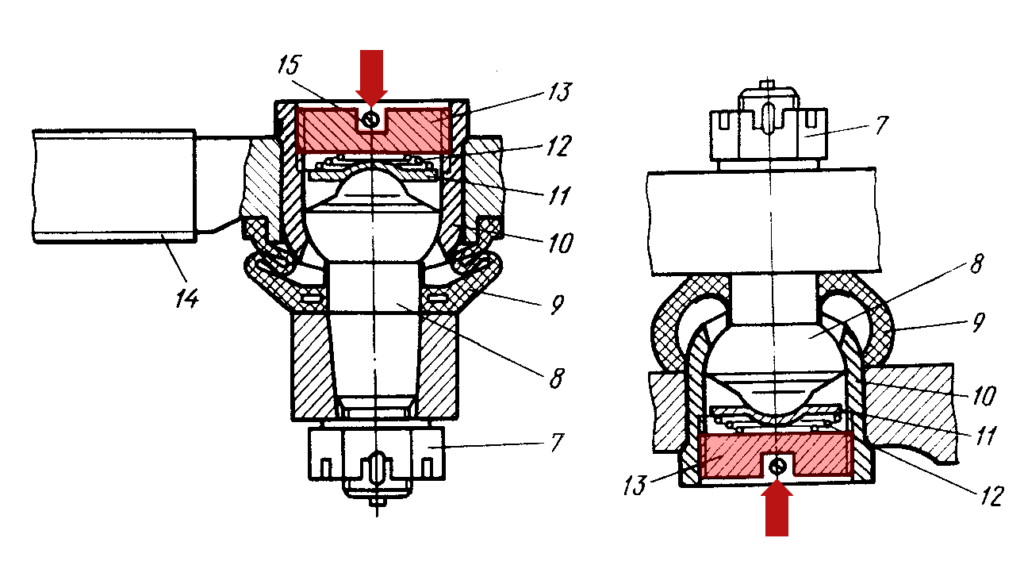

During assembly of the suspension, the trunnions also should be lubricated with a molybdenum disulfide grease before they are installed.

Steering linkage joints do not have grease nipples and do not need periodic greasing (unless the rubber boot gets ripped), but every 60,000 to 80,000 km (under favorable road conditions) they should be disassembled for cleaning and re-lubrication, then reassembled, checked for wear and properly tensioned by tightening the bottom plug. The manual recommends to tighten the plug all the way, and then loosen one full turn for the outer tie rod ends and half-turn for the inner ones. A molybdenum disulfide grease should be used.

Universal joints were originally lubricated with SAE 50 weight aircraft motor oil; any heavy-grade motor oil or transmission oil will work just fine. Keep pumping until fresh oil starts to ooze out of all four seals. Thick grease should not be used, as per manufacturer’s requirements (it is possible, but the U-joints should be completely disassembled, thoroughly cleaned and lightly packed with the proper type of grease which is stable enough for this application; do not use regular cheap lithium soap-based grease, in is not suitable for this application).

Cooling system

The Volga’s engine has an aluminum alloy block, so make sure the antifreeze you use is fully compatible with aluminum alloys (which today is mostly the case, unless a particularly cheap and/or low quality coolant is used), and also with copper alloys (yellow metals), as the radiator and the heater core are made of brass and contain lead solder (G12+, G13 and many other modern “Organic Acid Technology” type coolants are not the best choice, as these types of coolants do not work well with yellow metals and especially with the lead solder; older G11 / “Inorganic Acid Technology” type antifreeze is preferable).

Use of tap water as coolant is inadvisable, as it is known to cause extensive corrosion due to the presence of aluminum / iron galvanic couple, and also leaves a lot of residue (water has been used by many owners back in the day, but nevertheless it is a bad practice which slowly but steadily causes irreparable damage to the engine block and cylinder wet liners); distilled or deionized water may be used with a good corrosion inhibitor in mild climates, but do that at your own risk.

On pre-1985 engines (ZMZ-24D and 2401) the cooling system pump was regularly lubricated with Lithol-24 brand or any other Yellow Lithium grease via a grease nipple (every 12 000 kilometers, according to the Manual). Use a grease gun; continue pumping until new grease starts to be squeezed out of the control hole on the housing (usually two shots would be enough). Remove the excessive grease to prevent damage to the belts and other rubber parts.

If you do not have access to the above mentioned sorts of greases, or wish to use any other type of grease (which is only appropriate, because much better greases are available today than Yellow Lithium), disassemble the whole unit, clean it, replace everything that needs replacing, and fill the bearings with the new grease (fill amount should be about 50%). Bechem Berutox FE 18 EP 2, Chevron SRI and similar modern high-temp polyurea greases may be used in the pump bearings without any need for re-greasing (“lubricated-for-life”), or at least with a drastically reduced interval between lubrication.

In any case, consider disassembling the pump and replacing the old grease, because it is usually in unserviceable condition basically because of its age. The bearings and the rotor are also usually in a bad shape and should be replaced. GPZ 20703 bearings were originally used, internationally available analog is 65203 RS. Be warned that disassembling a used water pump quite often may be a one-way operation.

On engines manufacture after 1985 (ZMZ-402.10 & 4021.10), the pump bearings are lubed for life at the factory and in theory do not need any additional lubrication (some pump housings still have a threaded hole for the grease nipple, but no nipple itself, just a plug). However, in any case, the water pump in any old car usually needs overhaul. The bearings for this newer version of the water pump are made as a single unit, p/n 2101-1307027; it is a Lada part that is widely available. Factory grease is Bechem Berutox FE 18 EP 2, or similar.