The context

In late 1950s and early 1960s, the USSR enjoyed a rapid economic growth and social transformation during the process referred to as the The Khrushchev Thaw. The austerity of the immediate post-war decade was gradually being replaced by some semblance of wealth and prosperity. Among the highlights of this era were the Sputnik, the Khrushchyovka mass-produced housings, large-scale road construction – and new cars.

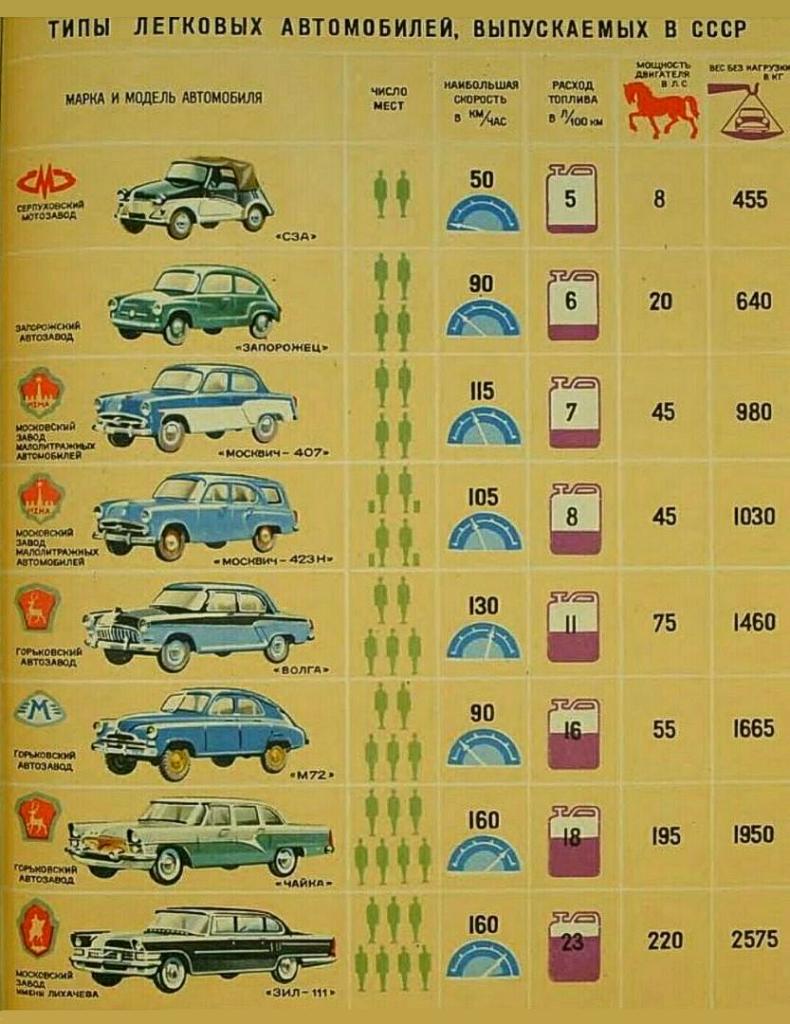

As of 1955, only four types of cars were produced in the country, of which only two were available to the general public. During the next decade, however, a whole bunch of new makes & models came in – small, large, medium-sized, rear-engined, front-wheel drive, four-wheel drive, etc.

By the early 1960s, the USSR produced a full range of passenger cars, from the microcar-sized SMZ & ZAZ, to the full-size sedans & limousines by GAZ & ZIL; most of them were recent all-new, clean sheet designs.

The GAZ-21 Volga, introduced in 1956, was an ambitious project, with its all-new OHV aluminum engine, automatic transmission and many other modern features, but the chassis, which was for the most part a carryover from the previous model, the M-20 Pobyeda, and the styling, which was largely based on the American style trends of early 1950s, were dated from the beginning, and didn’t age well. The need for a more modern replacement arose.

The Chayka

Early in 1959, the GAZ plant finalized the development of its newest model, the aluminum V8-powered GAZ-13 Chayka, which was designed to replace the dated GAZ-12 ZIM as the executive car for the mid-to-high level nomenclature (Communist party-approved governmental officials, civil and industrial leaders). It employed the most advanced technology available to the manufacturer at the time.

It comes as no surprise that when the same design team started working on a new medium-sized car, they initially envisioned it as scaled-down version of the Chayka, with a cruciform frame separated from the body and a V6 engine under the hood. In fact, the earliest stages of its development overlapped in time with the late stages of work on the Chayka, and a lot of its technical elements were carried over into the new project. E.g., the GAZ-24 Volga front suspension is essentially a scaled-down version of the Chayka suspension.

In the beginning

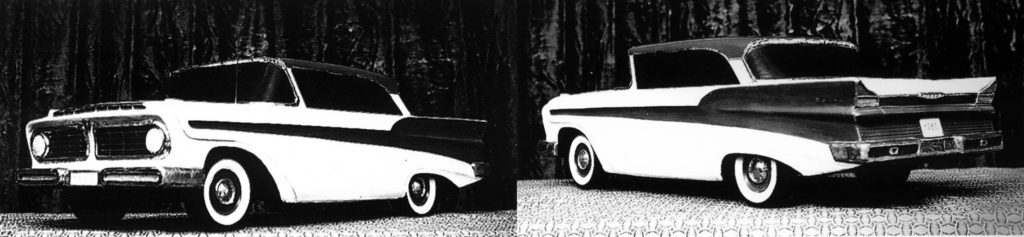

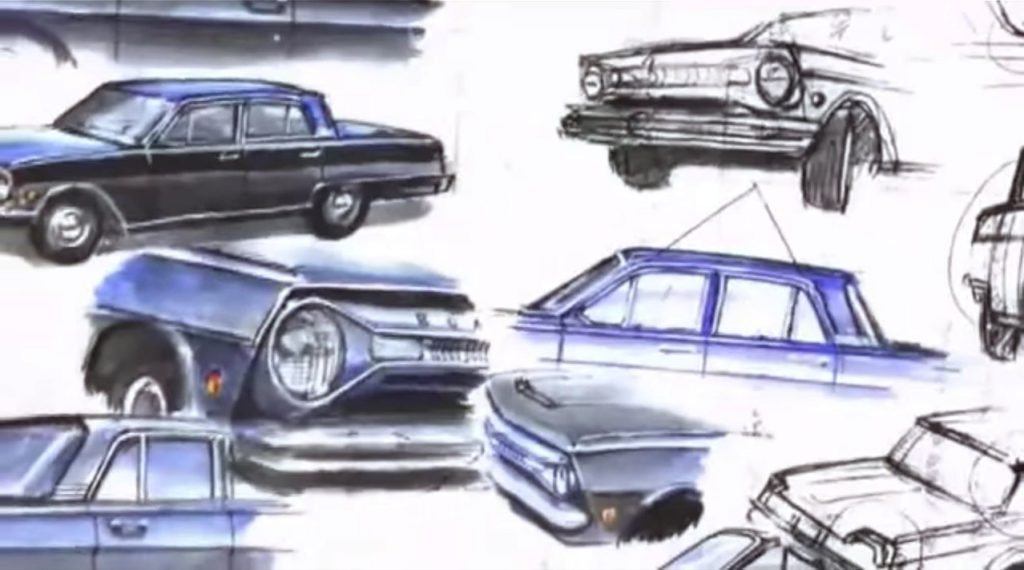

During the early stages of its development, the second generation Volga was a very different car compared to the final design. It was a body-on-frame car with a taller body and the styling reminiscent of the chrome-laden tailfinned American cars of the late 1950s, bearing a strong “family resemblance” to the Chayka.

This didn’t last long, however, as the designers quickly found out that the separate frame added way too much weight and took too much space under the passenger compartment’s floor, and the styling trends changed dramatically in the early 1960s, with much cleaner, crisper lines coming into fashion. Further development centered on a fully unitized body structure (with a front subframe welded to the body, unlike the GAZ-21’s bolt-on subframe) and a more “down to earth” look.

Styling

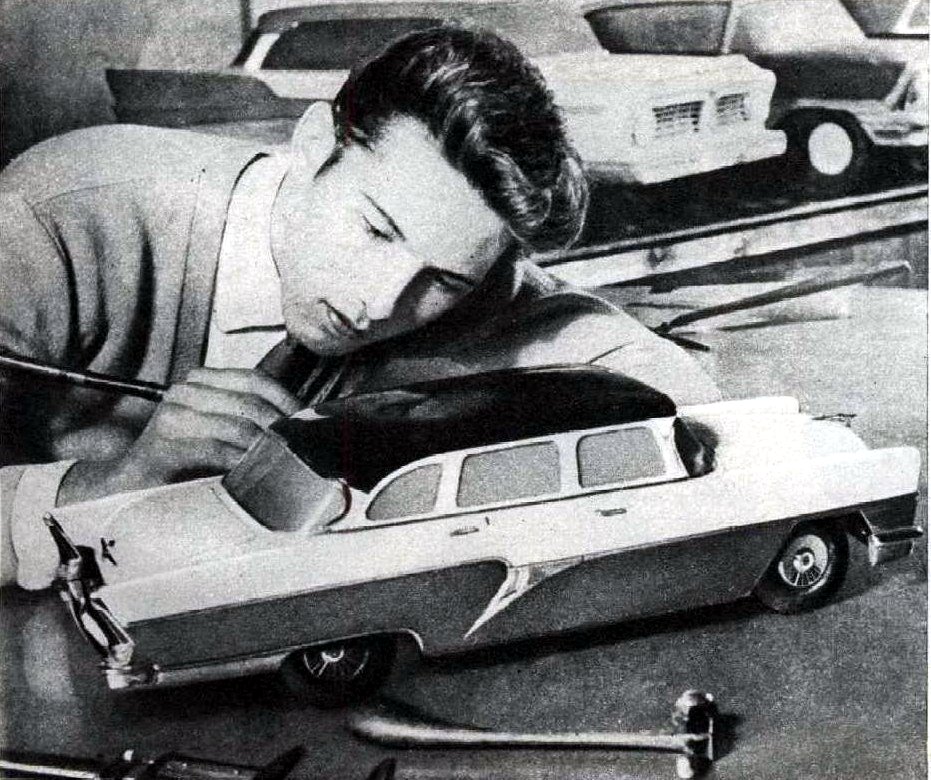

There were two competing styling teams working on the project: one was led by Leo Yeremeyev, already a well-known Soviet automotive stylist and the creator of the GAZ-21 and the ZIL-111; the other was headed by Leonid Tsikalenko, a young (28 years old at the beginning of the project) and relatively unknown sculptor from the plant’s Experimental Design Department.

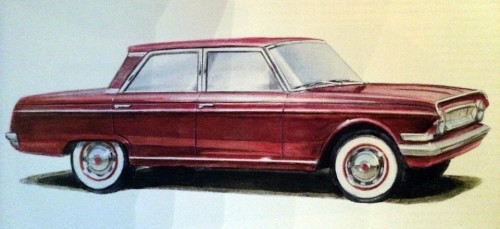

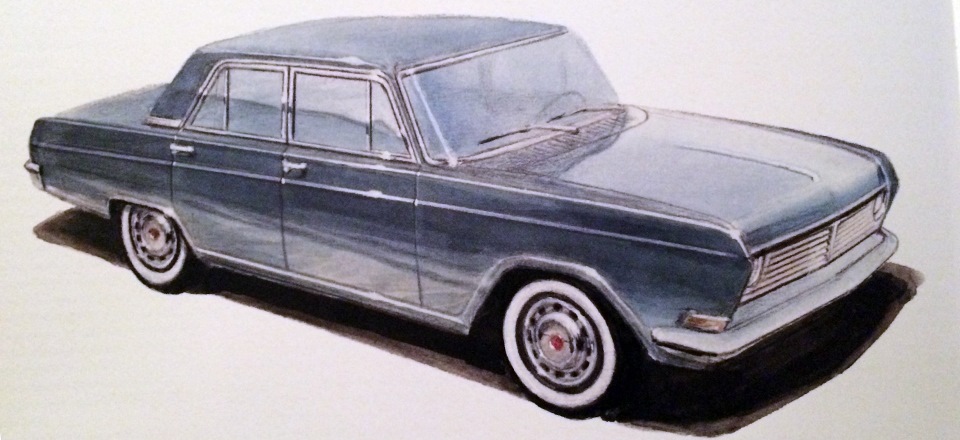

The initial proposal by Leo Yeremeyev (dated 1960) was essentially an updated version of the GAZ-21’s styling, with a more modern, squared-off look, but still featuring the outdated “two-storey” arrangement of headlights and grille. It didn’t go anywhere.

Tsikalenko’s team’s 1960 proposal was perhaps more adequate, however, none of the two made it to the next stage, as the styling trends continued to shift rapidly.

Yeremeyev’s 1961 proposal was still stylistically based on the GAZ-21, incorporating some features from the Chayka as well; it also had some similarities with a number of Italian cars of the time. It was developed to the stage of a full-size clay mock-up.

Tsikalenko’s team’s answer was quite a departure from the previous year’s design and already possessed some of the elements that later would be incorporated into the final version of the car.

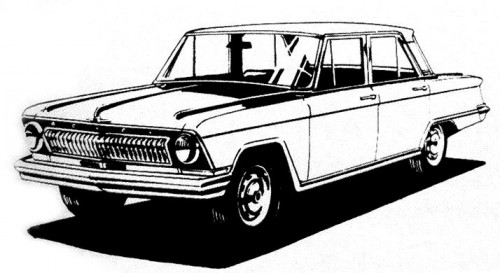

1962 version of Yeremeyev’s design retained most of the 1961 mock-up’s central body section, but featured an entirely new fascia, finally with the headlights integrated into the frontal ensemble and a vertical bar grille stretching between them.

Three completely roadworthy prototypes (chassis № 1, 2 & 3) were built based on this styling proposal during the winter of 1962 – 1963 and the early spring of 1963.

They were powered by an experimental “torch-ignition” four-cylinder stratified-charge engine, which, in addition to the conventional inlet and exhaust valves, employed a third, supplementary inlet valve (one per each cylinder), which charged the pre-chamber around the spark plug with a very rich air-fuel mixture. At ignition, a torch of chemically active combustion products shot from the pre-chamber into the cylinder, which was charged with a very lean mixture, resulting in more complete combustion of fuel and improved efficiency.

Three more prototypes (chassis № 4, 5 & 6) were built according to the styling proposal made by Tsikalenko and another member of his styling team, Nikolay Kireyev.

One of them was powered by an experimental 3.0 L OHV V6 engine developed in-house by Harry Ewart, which was 30% more powerful than the four-cylinder, and only a little more gas thirsty.

In the meanwhile, Tsikalenko’s team was gradually improving it’s version, experimenting a lot with different treatments for the front fascia, the roof pillars, the wheel arches and the side window frames.

The decisive year for the Volga’s styling was 1964. By that year both teams came up with their final proposals, and the 10th of January session of the plant’s Art Council was bound to make the final choice.

Yeremeyev’s 1963 design moved in a completely new and different direction, incorporating sharp blade-like fender extensions, clearly inspired by the iconic 1961 Lincoln Continental. The Art Council was displeased by this element, and also pointed out on some other deficiencies of the proposal, considering it slab-styled and “coffin-like”. The mock-up was also tested in a wind tunnel, and performed remarkably poorly even by the standards of its day.

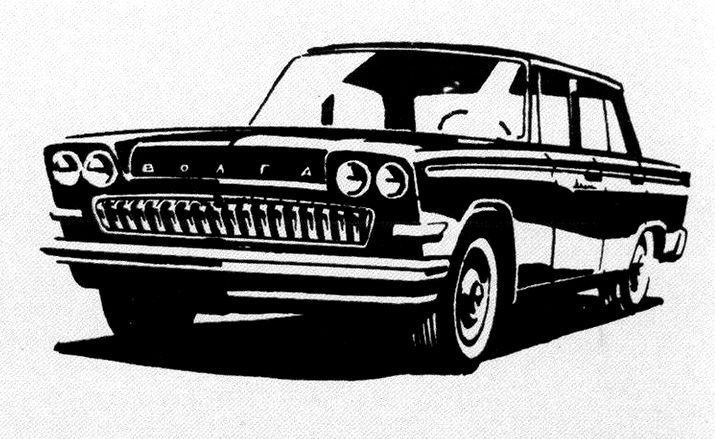

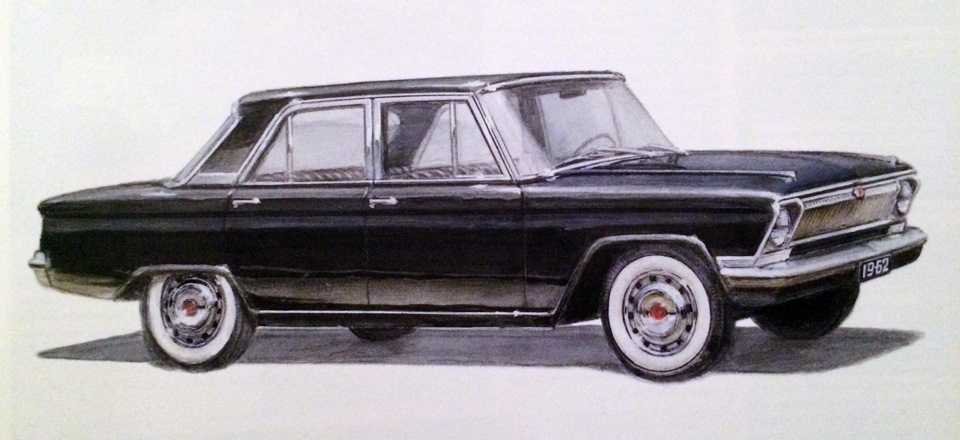

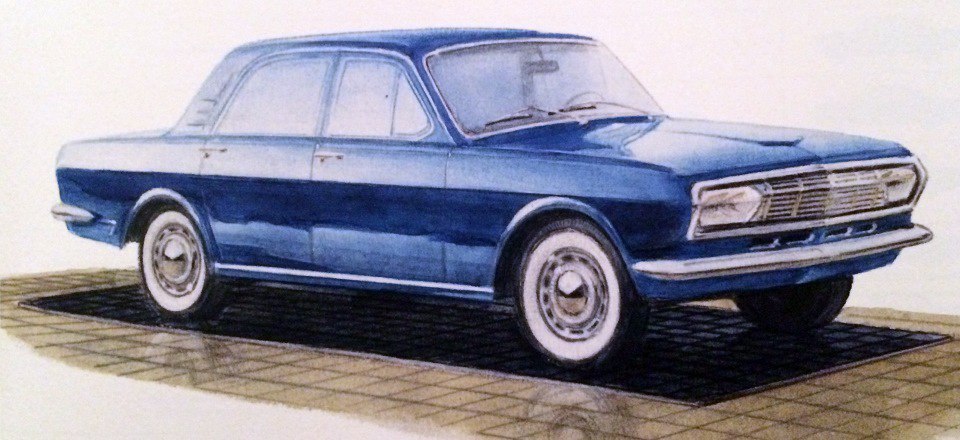

Tsikalenko and Kireyev finalized their design during the last weeks of 1963. This result of the gradual evolution of their original 1961 proposal featured a smoother, more rounded-off and, dare I say, more “European” shape – compared to the clearly and obviously American-inspired Yeremeyev’s proposal, while still using the classic “three-box” design language, typical for the large American cars of the time.

That was just what the Art Council wanted. They also noted many small, but noticeable original features, such as the design of the triangular vent windows with small “kinks”, or the fender-mounted rear view mirrors. Yuri Dolmatovsky, a famed automotive designer from the NAMI research institute, was present at the session and came to be a big supporter of Tsikalenko’s project. This version also fared significantly better than the competition in the wind tunnel tests.

During the later stages of development, the only major departures from the original project, as it was conceived by Tsikalenko, Kireyev and the others in 1964, were the replacement of “crystal” hexagonal headlights, planned for the “deLuxe” V6-powered version, with four round units, and the discontinuation of the fender-mounted rear view mirrors (in March, 1968), which proved to be quite impractical in real life. Also, different C-pillar treatments were tried out.

Prototypes & tests

The third (and final) series of prototypes was being built from September, 1964 (chassis № 7 & 8) to mid-1966 (up to chassis № 18). Eventually the prototypes with chassis № 7 and № 8 were showcased in the Kremlin and approved for further development by the Ministry of the Automotive Industry.

Prototypes with chassis № 12 (white) and № 17 (red) were specifically built for the production of promotional materials, with an exceptional quality of fit & finish. Prototype № 17 was also exhibited at the VDNKh trade show in Moscow late in 1968.

The last prototype with chassis № 18 was built for the purpose of applying for patents in the foreign countries that imported GAZ cars.

Other prototypes were used in various tests, including comparison tests with the Western cars.

The legally required State Acceptance Tests took place between August, 28 1965 and February, 20 1966. Several new Volgas, both with four-cylinder engines and V6’s, were thoroughly tested along with the current Volga model – 1965 GAZ-21S (two cars), as well as a bunch of foreign cars, including a 1963 Mercedes-Benz 220 Sb, a 1964 Ford Falcon station wagon, a 1964 Chevrolet Chevy II and 1965 Opel Kapitan & Fiat 2300 Familiare (wagon).

The cars traveled from the city of Gorky to the mountains of Caucasus, then to the steppes of Crimea, then to Moscow and back to Gorky, covering about 10 000 km altogether. The next stage was a long-term durability test of 30 000 km, as well as 10 000 km of various other tests.

The results of the tests were not ideal. The new engines still had some teething problems, and the electric system produced all sorts of malfunctions. Moreover, the prototypes came to be significantly heavier compared to the original specification (up to 180 kg of overweight), resulting in 0 to 100 km/h acceleration time being about 3 seconds worse than it should’ve been.

One of the other major criticisms was the high level of interior noise compared to the foreign cars, both coming from the engine and transmission and wind noise.

Still, in general the new model performed satisfactorily in the tests and was accepted for mass production by the autumn of 1966.

Simultaneously the car’s export potential was valued by the Avtoexport (the state-run trade organization that represented the Soviet automotive industry abroad), and the results were not very encouraging. The experts heavily criticized the car’s styling, finding it lacking in refinement, and named the four-cylinder engine and the lack of disk brakes as major deficiencies. The new car’s potential appeal in export markets was estimated to be rather low, and as the result the Avtoexport was not very interested in it.

Production

Mass production of the new Volga model was postponed for two economical years because of the teething issues, as well as the plant’s getting additional orders from the Ministry of Defense due to the beginning of the Arab–Israeli war of 1967 and the ensuing heightening of international tensions, including the rushing into production of the BTR-70 (GAZ-4905), a new model of an armored transporter, which took a considerable amount of time and resources.

While several pre-production cars were assembled in the end of 1967, and small-scale production started in 1968, only slightly more than two hundreds were built before 1969, and almost all of them were issued to various state-owned vehicle fleets for further testing.

The car started to be built on the GAZ plant’s main assembly line late in 1969, simultaneously with the continuing assembly of the old model. Finally, on July, 15th 1970 the last GAZ-21 rolled off the assembly line, leaving GAZ-24 as the only model of passenger car produced by the factory.

Little did anyone know at the time that it was going to be a beginning of a whole new era for the GAZ plant’s passenger car production – an era that would last until the first decade of XXI century…

The V6 engine did not make it into final production, although its availability “at some point in the future” was still announced as late as in 1973. The “torch-ignition” inline-four also did not survive the rigors of testing and had to wait for ten years, until the next Volga model came in and the environmental concerns reignited the interest in “torch-ignition” technology.

As the result, almost all the production cars were equipped with conventional OHV four-cylinder engines, with two valves per cylinder and a 2-barrel carburetor, available with either high or low compression ratio. Other engines were installed occasionally, domestic and foreign, but in very low quantities.

Still, the new car was quite a leap forward for the GAZ, and putting it into production required a major reconstruction of both the plant itself and many of its partners, including the Zavolzhsky Motor Plant, the Bor Glassworks, the “Red Etna” factory – as well as the construction of several new plants in Gorky, such as the Dies and Molds Plant (1967) and the Gearbox Plant (1968).