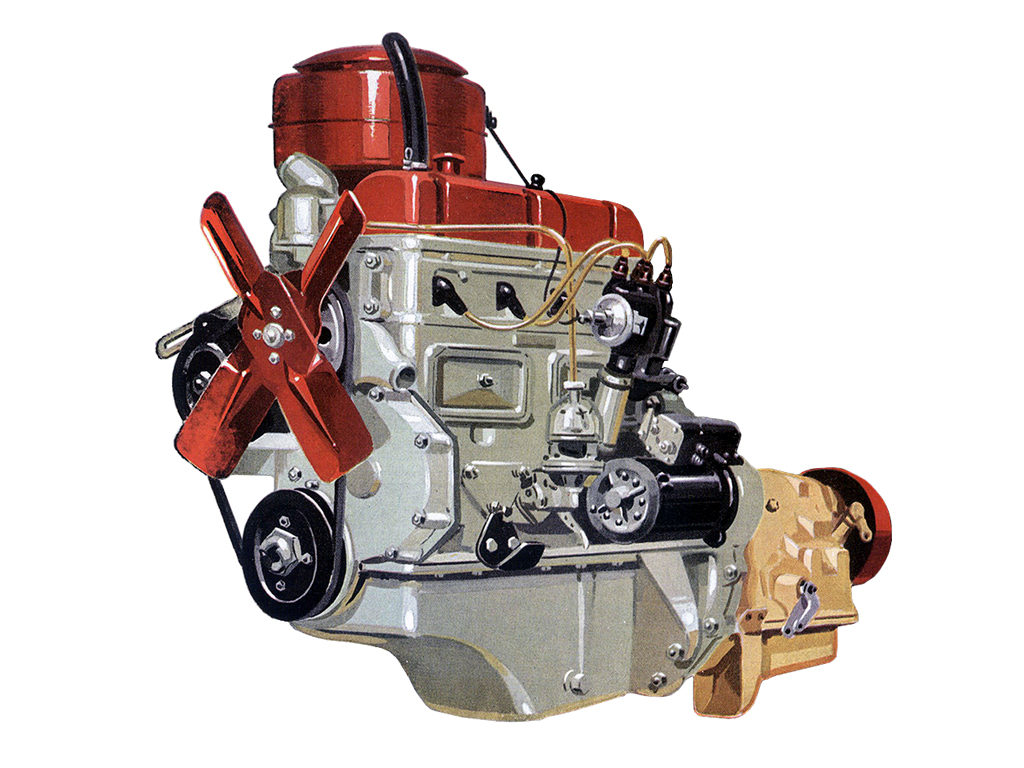

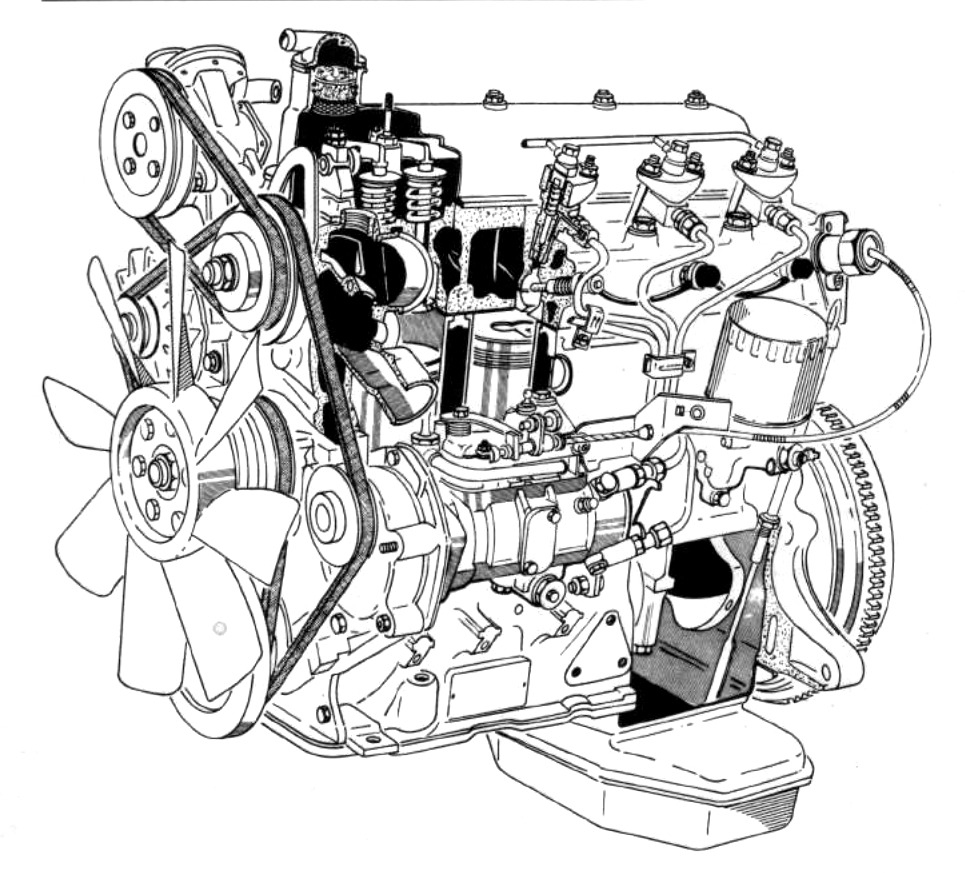

- 4 cylinders, 2445 cc / 149 ci

- 92×92 mm bore and stroke, giving 1:1 bore/stroke ratio (“square” engine)

- aluminum alloy open-deck block with replaceable cast iron wet-liners

- aluminum alloy pistons with floating pins and two chrome plated compression rings

- aluminum alloy reverse-flow cylinder head with cermet valve guides & high-strength cast iron valve seats

- aluminum alloy intake manifold, 2-bbl carburetor

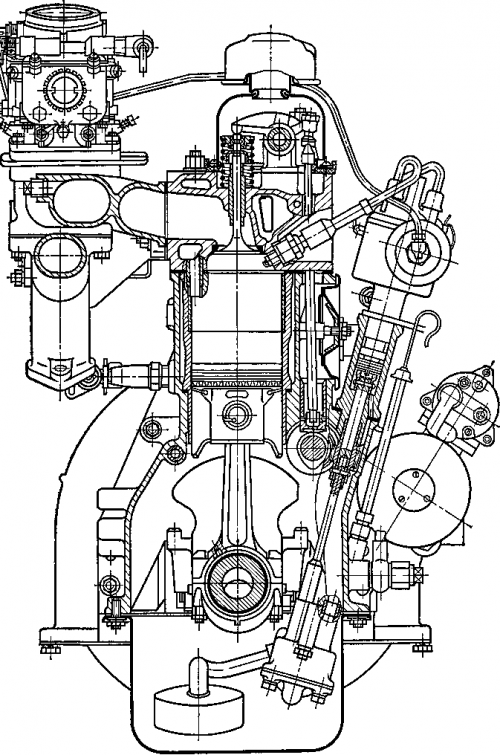

- overhead valves, cam-in-block, pushrod valve-train, solid lifters

- two compression ratios available – 8.2:1 (model 24D) or 6.7:1 (model 2401)

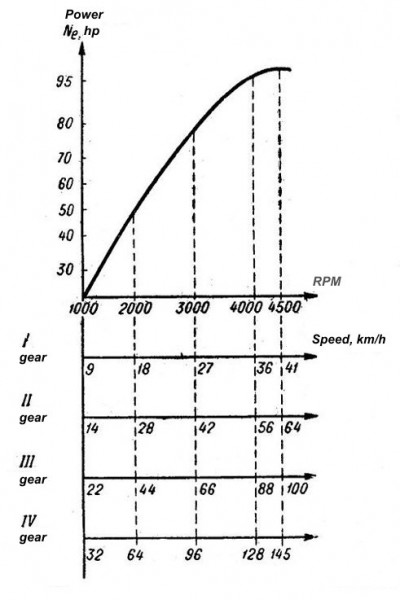

- max power output: 95 hp (gross) @ 4400 RPM for the high-compression version [also sometimes cited as 110 SAE hp for export markets]

- max torque output: 186 N·m (gross) / 137.4 ft·lb @ 2200…2400 RPM (high-compression)

- very flat torque curve between 1500 and 3500 RPM

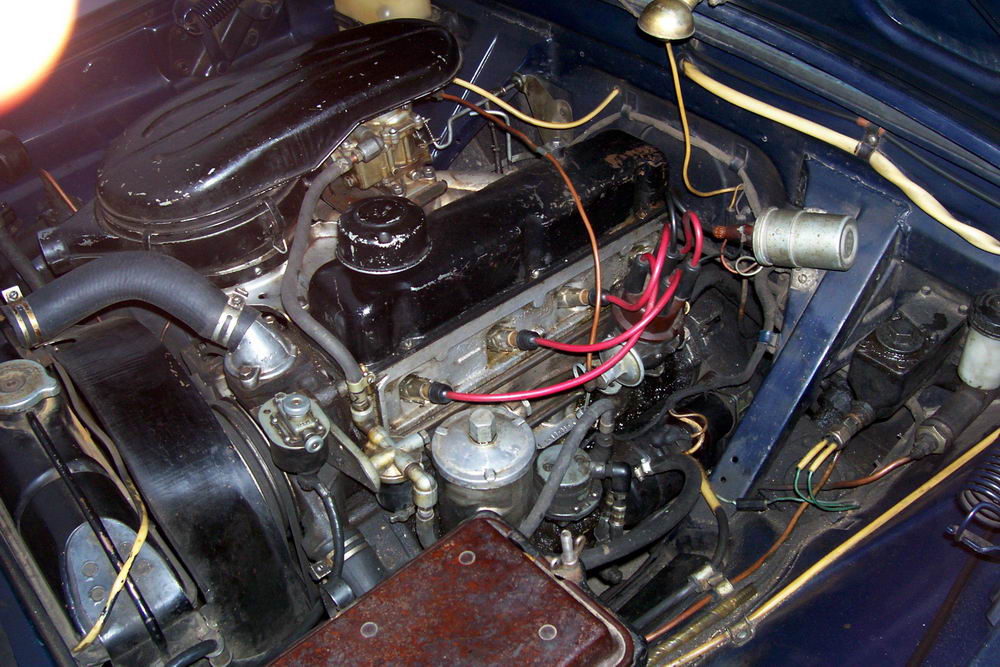

The absolute majority of GAZ-24 Volga cars came equipped with the four-cylinder gasoline engine which was produced by Zavolzhye motor plant (ZMZ) and available in two versions – the 24D and the 2401 – that differed only in compression ratio (D does not stand for “Diesel”; the 24D should not to be confused with diesel engines available in the Volga on some foreign markets). The low-compression 2401 engine, despite slightly lower horsepower (85 vs. 95 hp) and torque ratings, was by far the most popular of the two, as it could run on lower grade fuel which was both cheaper and more available in remote areas of the country; most of the taxicabs were equipped with this engine as well.

GAZ-24 Volga’s engine was largely derived from the GAZ-21 Volga’s model 21A powerplant, produced from 1957–1970, which itself had been originally developed by Harry W. Ewart for the GAZ-56 1.5-ton truck. The GAZ-21 engine also spawned a whole line of 2.5 & 2.9 L engines produced by Ulyanovsk Motor Plant (UMZ) and originally used in UAZ trucks and off-road vehicles.

In turn, the GAZ-24 engine eventually became the basis for the “torch-ignition” 4022.10 (1981–1994; 3 valves per cylinder, lean burn, stratified charge) and the 402.10 (1985–2005; larger exhaust valves, new water pump & different circulation of coolant in the engine, “breaker-less” electronic ignition, added emissions control equipment, etc.) engines.

Altogether these powerplants form the venerable family of GAZ / ZMZ / UMZ overhead-valve, cam-in-block engines, which soldiered on until mid-2000s (a 2.9-liter version with EFI is still produced by UMZ and used in modern GAZ commercial vehicles, although it is gradually being replaced by Diesel engines).

In a nutshell, in its original factory configuration it is a pretty typical low-revving overhead-valve four-cylinder engine of its time, designed & built with ruggedness, durability and ease of repair in mind, but with relatively little care for performance or fuel efficiency.

That formed the basis for a popular myth that it is a low-revving engine by default, which is not true, as its low-revving nature is determined by the factory configuration of camshaft, intake, exhaust, carburetion etc., and not any fundamental limitations of the design itself.

In fact, it is a “square” engine (92×92 mm), and the 2.9 L version is over-square (100×92 mm). Its relatively low max revolutions and ability to deliver peak torque at very low RPM are not inherent features, but rather a result of deliberate “detuning” by the engine’s designers. It was a trade-off for greater longevity, reliability and low-end torque, which were far more desirable features in a mass-produced engine than slightly more horsepower at peak RPM.

Racing versions of the Volga pushrod inline-four can safely rev up to 6500 rpm and produce 150 hp or more. Of course, they differ from stock engines almost as much as a NASCAR pushrod V8 engine differs from a stock pushrod V8. And yes – people *did* race on these engines (a lot !), and some still do.

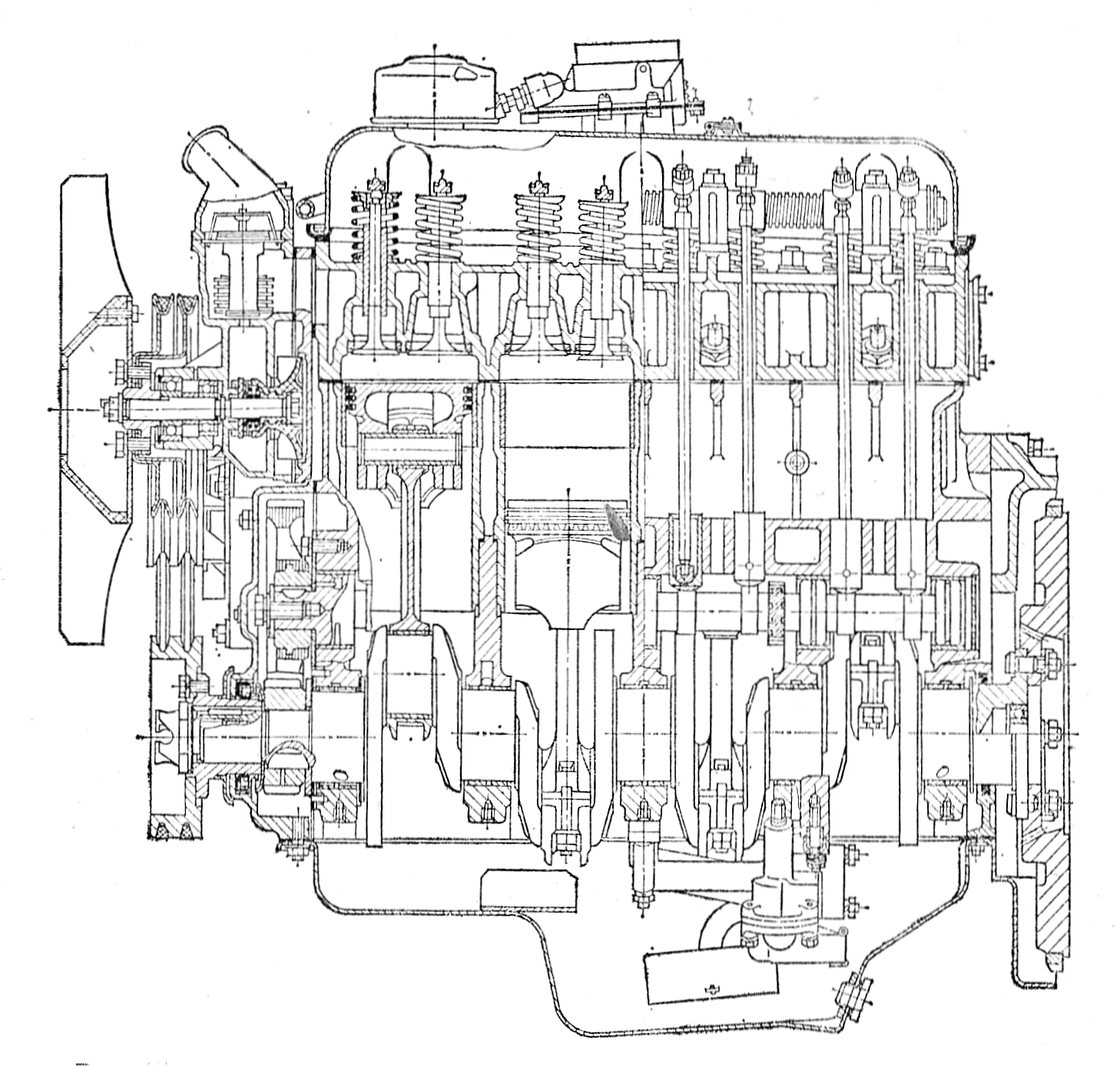

Lightweight aluminum alloy cylinder block (lighter than the much smaller Lada engine cast iron block) was injection-molded – a manufacturing process initially designed in the early 1960s at Zavolzhye motor plant for the manufacturing of the aluminum truck engines, heat treated and impregnated with a special kind of synthetic resin to fill the pores of the casting (which prevented oil leaks). Unlike 21A, 24D/2401 engines employed “long-skirt” or “deep-skirt” design of the crankcase – that is, the cylinder block’s casting had and extension below the centerline of the crankshaft, adding to the overall rigidity and making the oil pan gasket, which was now one-piece instead of a 4-piece set, much less prone to leaks.

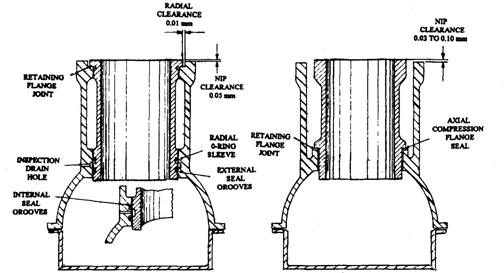

Replaceable wet-type cylinder liners (also called sleeves) were spun-cast from special high-strength alloy cast iron and machined to fit the block. Short dry-liners cast from acid-resistant cast iron were pressed into the upper part of the bore of each wet-liner (where most of the combusting takes place and the conditions are most severe) to further improve durability.

During the assembly of the engine the wet-liners were fitted into the block and sandwiched between the copper seal ring at the bottom and the cylinder head gasket at the top. With proper assembly tolerances, this design was mostly trouble free for the whole life of the engine, unless it overheated badly, which could cause cooling agent leaks into the cylinders (protrusion of the wet liners above the top surface of the block is especially important for the correct functioning of this design, see below).

Nip clearance (cylinder liner protrusion) is especially important for the correct functioning of this design, because it determines whether the head gasket will be crushed evenly and seal the water cooling jacket around the liner, or not.

If not, coolant leaks will ensue, either into the cylinders (no, or insufficient, clearance, or liners “sunk” in the block), or to the outside (too much clearance). Factory spec is 0.02–0.10 mm. Nip clearance must be the same for each liner of an engine, as well.

This design was neither cheap, nor easy to produce; for instance, the liners had to be manufactured in several different sizes (with separate size groups for sealing diameter and height) to make individual fitment to a particular cylinder block possible. The copper seal rings which were used in their seats were also produced in varied thicknesses and could be used as shims to adjust the position of a liner in the block, if that was required to ensure correct seating.

However, it had a substantial economical effect in the long run, as replaceable liners saved a tremendous amount of time, labor and costly machining time during engine rebuild. For this reason, almost all car engines designed in the USSR after mid-1950s used aluminum blocks with replaceable cylinder liners, as well as many truck engines (UAZ inline-fours and GAZ truck V8s; ZIL used cast iron blocks with wet liners). Also, aluminum could be pressure cast & machined at much higher speeds than cast iron, making it more suited to mass-production.

When this engine was designed, it was often easier to hand-fit the sleeves to a particular block than to find complicated machine tools required to bore and hone it during an overhaul. The sleeves themselves also could be bored and honed individually, which was still a much less demanding task than boring and honing a complete block, because it could be done in a regular lathe.

During 1970s and 1980s, however, engine repair facilities were becoming more widespread and much better equipped, making this design less and less relevant. The “next generation” GAZ four-cylinder engine that the plant started developing in late 1970s (the predecessor of the ZMZ-406 family) used a cast iron block without replaceable liners / sleeves from the very start.

Modern 2.7 & 2.9 L UMZ engines, which are largely derived from the Volga pushrod engine, use an aluminum block with cast-in dry cylinder liners, which is a stronger and more reliable design.

No critical corrosion problems, usually associated with aluminum engines with wet-liners, were experienced even when water was used as the cooling agent, which had been the case until 1975 when the cooling system was modified to properly work with antifreeze (today it is strongly not recommended to use water as cooling agent, nonetheless).

Due to light weight, relatively large displacement for the inline-four layout, heavy pistons and lack of balance shafts to smooth it’s shake, the Volga’s engine suffered from inherent more-than-usual amount of vibration, worsened by the relatively crude balancing technology used back then. To counter it, the designers employed thick rubber engine mounts, extra-soft rear transmission mount which used coil springs instead of rubber (after 1976) and elastic rubber joint in the transmission tail shaft housing (after 1976).

Yet, the engine still was not as smooth as an inline-six of the same displacement could have been. Severely out-of-tune, or assembled without proper attention to balancing, it could turn the otherwise comfortable Volga into a traveling fatigue machine. If properly manufactured & tuned, however, it runs reasonably smooth and quiet.

Compared to modern gasoline engines, the Volga pushrod four is almost like a diesel in terms of performance. It doesn’t have much maximum power at peak RPM, but it makes considerable low-end torque, and, consequently, generates considerable low-RPM power (roughly 50 hp / 37 kW @ 2000 RPM). 50 hp doesn’t sound like much, but a typical modern gas engine with the same peak power of roughly 100 hp would generate almost two times less power at the same RPM (about 30 hp).

Thanks to that extra low-end power and an unusually “short” gearing of the rear axle (4.1:1), the Volga’s acceleration from 0 to 60 km/h is much more lively than the max power-to-weight ratio of the car would suggest, which allows it to keep up with the modern city traffic.

It is still underpowered for modern highway speeds, however, and, while the engine’s peak power allows the Volga to (eventually) reach a top speed of almost 150 km/h, acceleration at speeds above 100 km/h is rather anemic, making overtaking difficult. The optimal cruising speed is about 110…120 km/h, and at higher speeds it feels as though the engine is working too hard.

Many owners install the five-speed overdrive gearbox that was used in the later Volga models (and was a completely new design, not related to the four-speed gearbox). That noticeably improves the situation, just as a “taller” rear axle gear ratio does (3,9:1 and 3,58:1 gear pairs are available). However, the trade-off of the latter modification is worse acceleration in city driving (which the five-speed gearbox compensates for to some degree, due to its lower first gear).

A lot of low-end torque and a relatively flat torque curve also mean that the driver doesn’t have to shift gears often in city traffic. First gear is quite “short” and normally only used for taking off (and a lot of drivers just omitted it and started off in second, which provided enough leverage against the pavement unless starting uphill; the practice was so common that the User’s Manual explicitly prohibits it, because it puts unnecessary strain on the components of the car). Third gear, on the other hand, is very flexible, and downshifting to the second is only required if you need a sudden burst of speed when going under 40 km/h.

All-in-all, the Volga’s performance was on par with the other cars of the same size class equipped with a big-bore four-cylinder engine or a small inline-six, e.g., Chevrolet Nova with the 153 CID “Super-Thrift” four, the other GM X-bodies powered by the 151 CID “Iron Duke”, or Chrysler’s A-bodies / F-bodies / M-bodies from 1970s & 80s with the slant-six (less torque than the six, but also better fuel economy).

Among the Soviet cars of the epoch, it was just a bit slower than most Lada models or the newer Moskvitch-412 and 2140, but still faster than the veteran Moskvitch-408 or the little Zaporozhets.

In the USSR, there were no speed limits for intercity roads until 1976, when a county-wide speed limit was set at 90 km/h / 55 mph. Later, a special 110 km/h / 70 mph speed limit was added for specifically designated highways.

While the Volga was considered gas-thirsty compared to other (smaller) Soviet cars, it actually consumed a reasonable amount of fuel for it’s size, weight and engine displacement. According to the manufacturer’s specifications, on highway at steady 80 km/h (50 mph) it consumed creditable 10.5 liter of gas per 100 km (22.4 MPG).

Under actual driving conditions, fuel consumption figures were higher, but still decent for a 1500 kg / 3000-pound car with a 2.5 liter engine, not going anywhere beyond 17-18 l/100 km / mid-teens MPG (see the graph). And, considering the fact that gas was ridiculously cheap in the Soviet Union, the Volga more than made up for the fuel it consumed in power, driving comfort and durability.

In the USSR during most of the 1970s the gas prices for individual motorists stayed at 1 rouble per 10 liters of 85 octane AI-93 and 75 kopeks per 10 liters of 76 octane A-76.

This is roughly equal to 11 and 9.8 roubles per 1 liter in 2013 roubles, or ¢36.5 and ¢32.5 respectively in 2013 US cents.

1 gallon is equal to 3.78 liters, so that would be $1.38 and $1.23 per gallon in today dollars. Just to remind, in the USA gas was about $2 per gallon in today dollars just before 1973 price shock.

Fuel crisis didn’t hit in the USSR until 1978, when the gas prices instantly doubled.

It was a robust engine, easily capable of at least 200,000 – 250,000 km (125 000 – 155,000 miles) before first overhaul, if maintained properly. Gentle driving and good care could extend it’s life to 300,000 – 350,000 km (190,000 – 220,000 miles) or even further, and such mileages were quite common for privately owned cars. The highest recorded mileage before first overhaul was 700,000 km (440,000 miles) by a GAZ-24-04 (station wagon taxicab) with a low-compression 2401 engine.

After the first overhaul, a properly assembled engine could run happily for another 150,000 – 200,000 km at the least, and many of them have had second or even third overhauls.

The updated Volga model designated GAZ-24-10 was equipped with ZMZ-402.10 (98 hp) or 4021.10 (88 hp) engines, which, once again, differed only in compression ratio. We’ll call them just “402 engines” for short.

They were largely based on the 24D / 24-01 family, but also featured some significant design improvements, which mostly came from the “torch ignition” ZMZ-4022.10 engine (the latter deserves a separate story).

“Torch ignition” engines had been an ongoing project for GAZ and ZMZ since mid-1950s, however only late 1970s brought the major breakthroughs that allowed to put them into mass production.

In addition to the conventional inlet and exhaust valves, “torch-ignition” engines employed a tiny third, supplementary inlet valve (one per each cylinder), which charged the pre-chamber around the spark plug with a very rich air-fuel mixture that came from the third barrel of the carburetor.

At ignition, a torch of chemically active combustion products shot from the pre-chamber into the cylinder, which was charged with a very lean mixture, resulting in a more complete combustion of fuel and improved efficiency.

As fuel injection systems became the norm, “torch ignition”, just as other “lean-burn” systems, became outdated and soon fell out of use.

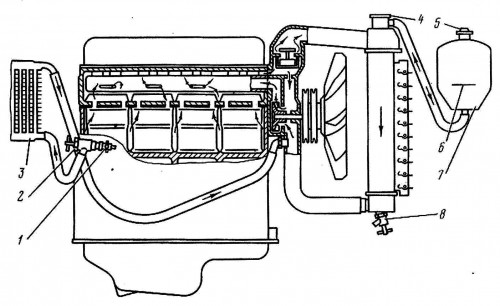

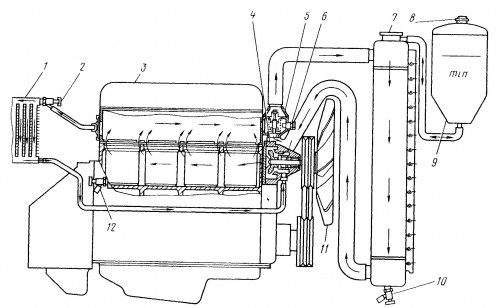

The most apparent difference between the 402 and the older 24 engines is the design of the cooling system.

Those older engines employed an engine-driven pump for coolant circulation inside the cylinder head, where a water distribution tube was used to control the flow, directing cool water from the pump to the “hot spots” – places where exhaust valve seats and spark plugs were located.

However, thermosiphon circulation caused by the temperature differential was relied upon for cooling the cylinder liners and moving coolant between cylinder block and cylinder head (cool water sinks down into the block, hot water rises up into the head).

That system worked reasonably well for relatively under-stressed engines, providing uniform cooling for all four cylinder liners. However, the 4022 “torch-ignition” engine ran much hotter and required an increased flow of coolant, therefore a more efficient cooling system was designed for it.

Later on, the mass-produced 402 family of engines inherited most of the features of this new cooling system.

In 402 engines, the pump was moved down from the cylinder head to the cylinder block. Therefore, coolant circulation in the entire engine now completely depended on the pump.

Coolant from the radiator was now pumped directly into the cylinder block and then forced by the pressure up into the cylinder head, passing via orifices in the head gasket (smaller orifices around 1st cylinder that was closer to the pump; more and larger orifices around 4th cylinder that was the farthermost). From the cylinder head it moved into the thermostat housing, and from there – into the top tank of the radiator.

Other improvements included larger exhaust valves, tuned exhaust system, “breaker-less” electronic ignition with a magnetic pick-up sensor, crankshaft harmonic damper and a new carburetor that lowered engine emissions (high-compression engines only).

402 engines were produced well into XXI century and used in Volga cars and GAZelle family of light trucks until 2005. A 2.9 liter version was produced as ZMZ-410.10 (trucks only).

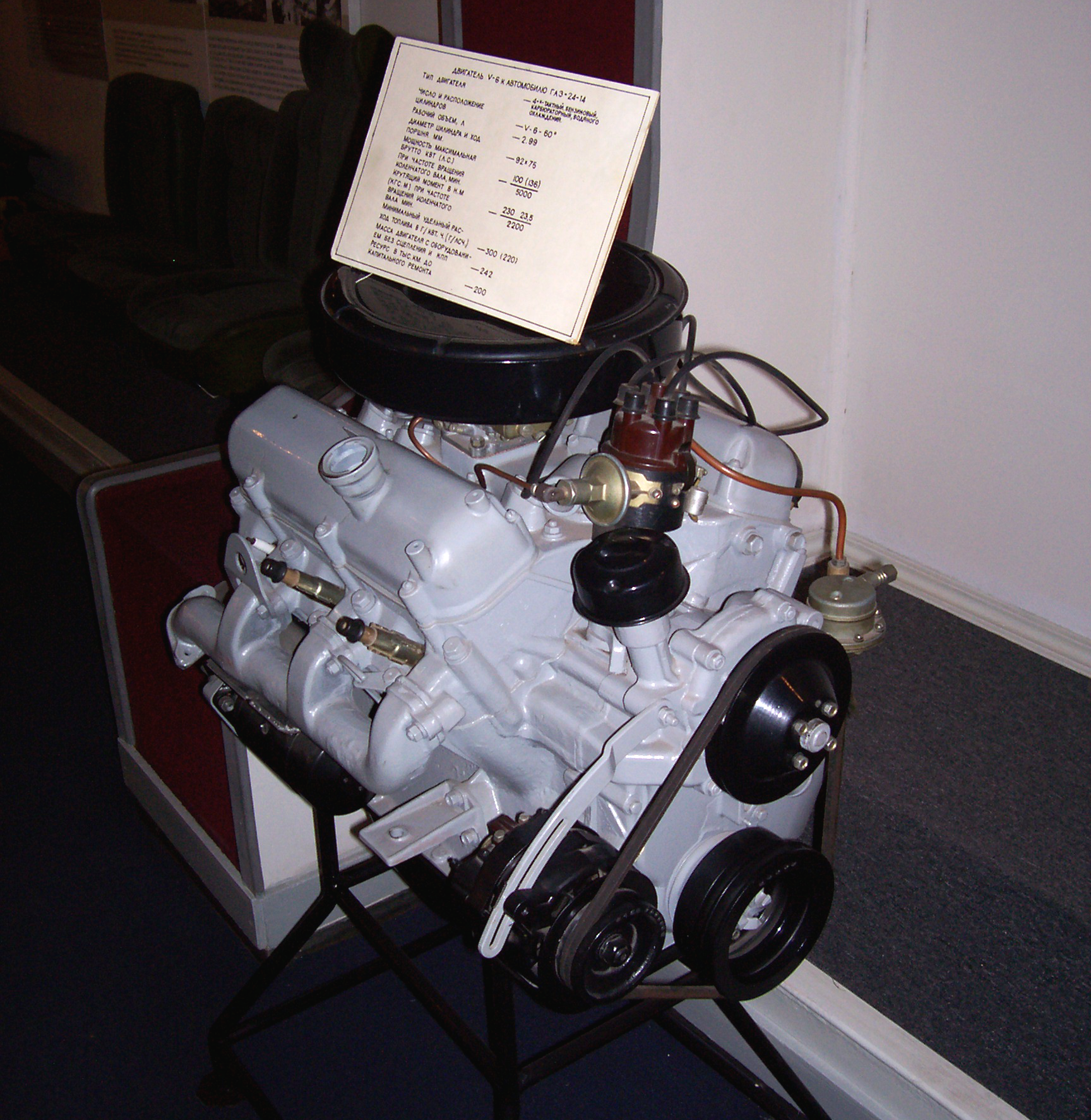

Some more photos of a factory V8 powered Volga.

Starting in 1973, a V8-powered version was produced in limited numbers, too, mostly for the law enforcement agencies, including the (in)famous KGB. The V8-powered Volga was designated GAZ-24-24 (24-34 in 1987-93) and nicknamed “the double” or “the catch-up”. Some of these cars indeed were used for pursuit applications, however the vast majority of them lived a more humble existence of an escort vehicle for VIP motorcades.

The aluminum V8 was a regular production engine without any performance upgrades, it had a displacement of 5.53 L / 340 ci and produced 195 hp (gross) with one 4-bbl carburetor (possibly slightly more for the later cars which had better flowing cylinder heads derived from GAZ-14 Chayka). It was a later design than the four-cylinder engine, and is often cited as a better one. It was coupled to a 3-speed automatic transmission, which dated back to 1950s-vintage designs (with some major upgrades).

All cars came with body reinforcements, heavy-duty suspension, standard power brakes (four-wheel drums with non-organic linings, except for some late production cars which had disk brakes with 4-piston calipers up front) and power steering (with a separate power cylinder). Some of them also had electric window regulators, air conditioning and other creature comforts usually not found in regular Soviet cars (most such cars were used by high-ranking officers of various security agencies).

GAZ-24-24 managed 0-100 km/h in 13-14 seconds and had a top speed of 170+ km/h (105 mph) – not a muscle car by any means, but absolutely adequate for the job it was built for.

The initial plan was for the “civilian” top-spec version of the Volga to be equipped with a 2.99 L 60° V6 engine. Several versions of this engine were developed by GAZ and ZMZ during 1960s and early to mid 1970s, with aluminum or cast iron block, both in cam-in-block and overhead cam configurations. None of them was ever developed to the point when it could be used in a production car, though, and the start of the fuel crisis in October, 1973 led to a dramatic fall in popularity of large-engined cars in Europe, making the V6-powered Volga much less marketable abroad and essentially rendering its production economically unviable.

The development of the V6 continued at a slow pace until 1977 or 1978, but ceased when additional manpower was required to develop the “torch-ignition” engine for the GAZ-3102. Roughly at the same time ZMZ started to work on an overhead-camshaft four-cylinder engine designated E403.10, which would eventually lead to the ZMZ-406 family of DOHC engines, still in production today.

Some production cars were equipped with foreign inline-6 or V6 engines, both by GAZ itself and its foreign dealers, e.g. Konela in Finland.

Some export versions of the Volga were equipped with 2.1 L Peugeot-Indenor XDP 4.90 diesel engine. They were sold abroad as M24D (sedan) and M24B (Break; “station wagon” in French).

Diesel cars were never popular in USSR because of their complexity, specific maintenance requirements and low fuel prices (and still have a somewhat doubtful reputation in today Russia). However, they have always been quite popular in Europe, and the 1973 oil crisis only spurred their popularity there, a Diesel engine becoming essentially de rigueur for good export sales. Some cars got their Diesel engines installed right from the factory, and others were converted to Diesel power by foreign dealers, such as Scaldia-Volga of Belgium.

The diesel was less powerful than the gasoline inline-four (62 hp), but provided excellent fuel economy (which has never been a strong point of the original engine), and also was very durable, making it ideal for fleet sales. Maintenance was not a problem because the same engine was used in Peugeot 404 & 505 models, as well as some other European cars and light trucks.