This is a brief Buyer’s Guide for the Volga GAZ-24 that is intended for prospective buyers from countries outside the former USSR.

Why would you want to buy a Volga

The Volga GAZ-24 is a very iconic vehicle of the Eastern Block which accounted for a major part of traffic on the Soviet roads in 1970s and 80s. While the Western public is more familiar with Ladas and Moskvitches from the same era, in fact the Volga was by far the most common car that a common Soviet citizen encountered on a day-to-day basis. Private-owned cars were relatively rare and the streets were ruled by trucks, state-owned Volga taxicabs and Volga cars owned by various organizations or assigned to industry managers, Soviet and Party officials, etc.

The Volga’s styling was strongly influenced by the trends of the American car building industry of its time, making it quite compatible with the American traditions of customizing and lowriding. While in the US the iconic lowrider would be a ’63 or ’64 Impala, in the former USSR the Volga is considered to be an acceptable substitute.

While prices vary greatly, generally the Volga is inexpensive for a mid-sized car with mid-1960s styling. It may be not as refined as the Western vehicles of the same era, but is a roomy and comfortable car in its own right that is absolutely adequate for modern driving conditions. It is neither too small, nor too large, is not critically underpowered and generally is practical enough to be used even on a daily basis, unlike some of the more mechanically complicated and/or exotic classic cars of the same vintage.

The car is mechanically simple and is for the most part easy to work on, making for a relatively simple and enjoyable restoration project. Parts are still abundant in the former USSR countries and a lot of reproductions are manufactured because the Volga is a very popular classic car there.

Cars on the same, or very similar, platform were manufactured in Russia well into 2000s, and a lot of parts from these later Volga models can be retrofitted to the older vehicles, if you are so inclined. That includes far superior suspension and brakes, as well as such amenities as modern power assists for steering and brakes. With relatively little effort and modification, the Volga can be turned into a very drivable car, while retaining the classic styling. In addition, the engine bay is roomy enough to accommodate a large V8, and the body is rugged enough to handle such modification (in fact, a factory built 5.5 L V8-powered version was produced in small numbers).

Which one to look for ?

It’s difficult for me to give any guidance on this matter because I’m not intimately familiar with the classic car market outside of Russia. However, some general directions still may be of some use.

Normally, only early GAZ-24’s are of any interest to serious car collectors, and the late ones (produced after 1976…1978) are much less desirable. Relative rarity and features such as more elegant exterior trim, ribbon-style speedometer or front bench seat (split) make the early Volgas distinctive and attractive. In fact, more than a few late cars today are being modified to look like the early ones by replacing such elements as bumpers, dashboards, seats, etc.

GAZ-24-10’s generally fall into “future classic” category and would only be considered a collector’s item in a flawless original condition.

Very early cars built before 1972…1973 and kept in original condition are quite rare today. They are also considered to be the best looking ones by many. However, be advised that these cars are only of serious interest if all of the body panels are original and do not need complete replacement, because these early panels slightly differ in shape from the later ones. As the stamping dies wore, body panels became noticeably smoother, with blunted edges. The differences are subtle, but they are one of the things that make these cars desirable. Finding suitable replacement panels is almost impossible because modern replacement parts are made on worn equipment and duplicate the smoother body panel geometry of the late cars.

If you get extremely lucky, you may even find one of 18,486 units built in 1970 (the first year of full-scale production). They possessed a lot of features not found on later cars, not all of which are even properly documented yet.

Low mileage cars are to be preferred. Usually less than 100,000 km of mileage means a relatively “fresh” car, with minor mechanical wear and original interior in decent condition (may still need some mechanical and/or body repairs). However, take into account that mileage meters on these cars only have five digits and would roll over at 99,999 km, so odometer reading is very unreliable. Look at the condition of the car, not the counter.

Any Volga that left the factory painted in any color other than white, black, beige or gray is a rarity by default. Some collectors even consider these four “junk colors” and avoid them completely, probably making some exceptions for extremely well-preserved black cars or the rare “Anthracite” charcoal gray.

Wagons are much rarer than sedans and well-preserved ones are very difficult to find. Ambulances in original condition, with most of the equipment still intact, are exceedingly rare, and prices have recently went exorbitant. Spare body parts that are specific to station wagons are getting difficult to get, so look out for rust damage in the rear (unfortunately, rear body sections of wagons are very prone to rust, especially the rear hatch and spare tire compartment).

Original GAZ-24-01 taxicabs are quite rare, however the market for such specialized vehicles is rather small.

Export versions are all rare and desirable, but especially so the cars modified by the foreign dealers, and most of all – cars with factory or dealer installed Diesel engines and V6’s (but only in original condition and not with a standard gasoline engine swapped in; the particular modification of Peugeot-Indenor diesel that was used in the Volga is next to impossible to find if one doesn’t come with the car). A car assembled and/or sold by Scaldia-Volga of Belgium (the major Western European dealer of GAZ cars) must have a second serial number plate with French text, Konela cars from Finland should come with Konela plate, etc.

Original V8 powered cars are in a league of their own in terms of rarity and collectability (or, more specifically – in the same league with the Chayka cars), with prices reflecting that fact. Today, there are much more replicas that original factory V8 cars, however they are relatively easy to distinguish.

Where to buy ?

Almost all Volga cars offered for sale on international online marketplaces are overpriced junk.

In Russia and most other ex-USSR countries, most of the old Volgas were used on a daily basis until 2000s or even 2010s. Hence, most of these cars are in bad condition and of no interest to a collector. The few good, original, one-owner or family owned low mileage cars that resurface in classified ads from time to time are almost immediately bought by the local classic car aficionados or resellers. Really good and rare cars are typically sold by collectors to other collectors, meaning that normally you should know people from these circles to even have a chance to buy one. There are still very few classic car auctions and large dealers, and the prices they offer are usually unreasonable. For all those reasons, chances to get a good car for an adequate price are quite low for a foreigner.

Probably the best place to buy a Soviet car today would be the Baltic states – Estonia, Latvia and Lithuania. First of all, they are all members of the European Union now, which makes finding, buying and exporting a car much more simple, especially for a customer from Europe. Secondarily, contrary to what their inhabitants may want you to think, these countries were quite wealthy during the Soviet era, and people there were buying a lot of personal cars as a consequence. Hence, a good choice of well preserved specimens.

Volga cars were sold in many countries of Central, Northern and Western Europe as well, and some of these exported cars resurface from time to time, usually as garage / barn finds.

What to look at ?

Serial numbers

The first thing to look at are the serial numbers. All GAZ-24’s and most of the GAZ-24-10’s were built in pre-VIN days, meaning that they have three separate serial numbers: one for the chassis, one for the body and one for the engine.

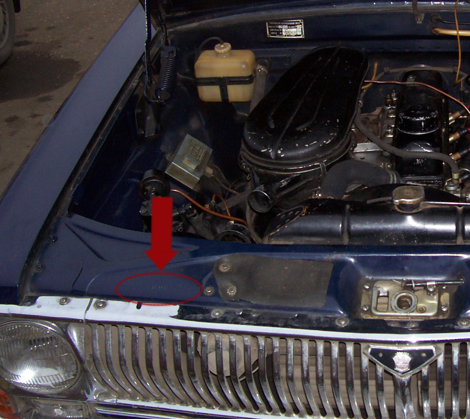

Body serial number is normally stamped on the hood lock panel, to the left of the hood lock if you are standing in front of the car (not a good choice, as it often gets damaged in road accidents).

Engine serial number is on the left side of the cylinder block, above the fuel pump and between the oil filter and the distributor. Very easy to find and almost always in good condition (another advantage of aluminum blocks).

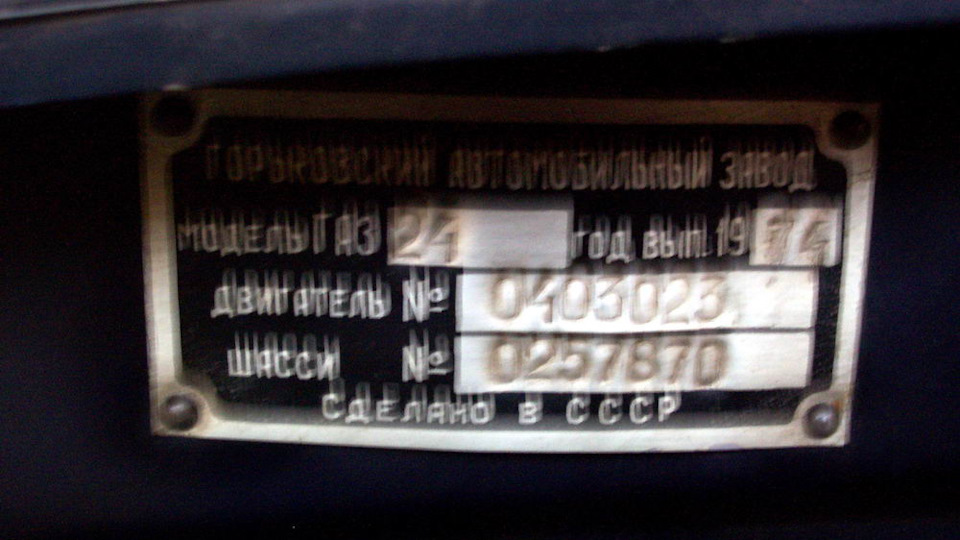

Chassis No 0257870

Chassis/frame serial number can be found only on the vehicle identification plate that is riveted to the firewall (right inner fender panel on GAZ-24-10). The plate also has the engine serial number inscribed on it, as well as the car’s model and (not always) year of manufacture.

Currently in Russia, engine serial number is not used for vehicle identification, and before that replacing the engine with an identical one had been simple enough already, so on many cars the engine serial number won’t match the number on the factory identification plate. Many replacement engines may not have any number on them at all (“numberless” engine), that’s perfectly legitimate here (unless the existing number has been destroyed by the owner, which may bring trouble).

All serial numbers must be clearly legible and match the numbers in the documents the car’s owner has. In some countries the engine serial number would be of no particular interest, but the body and, probably, chassis numbers would most likely be used in lieu of the VIN to identify the vehicle in any jurisdiction, so beware !

Cars that were assembled and/or sold by foreign dealers can have additional identification plates in French and/or English (or other languages).

GAZ-24-10’s and related models (built after 1985) have their identification plates on the right inner fender. Starting in 1990, a 17-digit VIN starting with letters XTH was used instead of separate body & chassis serial numbers, engine serial number was retained.

Body

While mechanicals of these cars are relatively simple and often can be sorted out without getting into much trouble or money, the body is the most expensive and difficult part to repair in the whole car. Extensive body repairs also cause a great loss of originality. So look very carefully for any damage.

Problem number one is rust. Problem number two is how people tried to fight it.

Just as many unitized-body cars of the past, the Volga is full of rust traps. And, if rust proofing is not regularly maintained, they will eventually turn it into a rust bucket. Body repairs were usually done in an amateurish way and with crude equipment such as gas torches or electric arc welders.

Avoid any cars with extensive rust or signs of extensive welding repairs. Quality of such repairs is almost always sub-par.

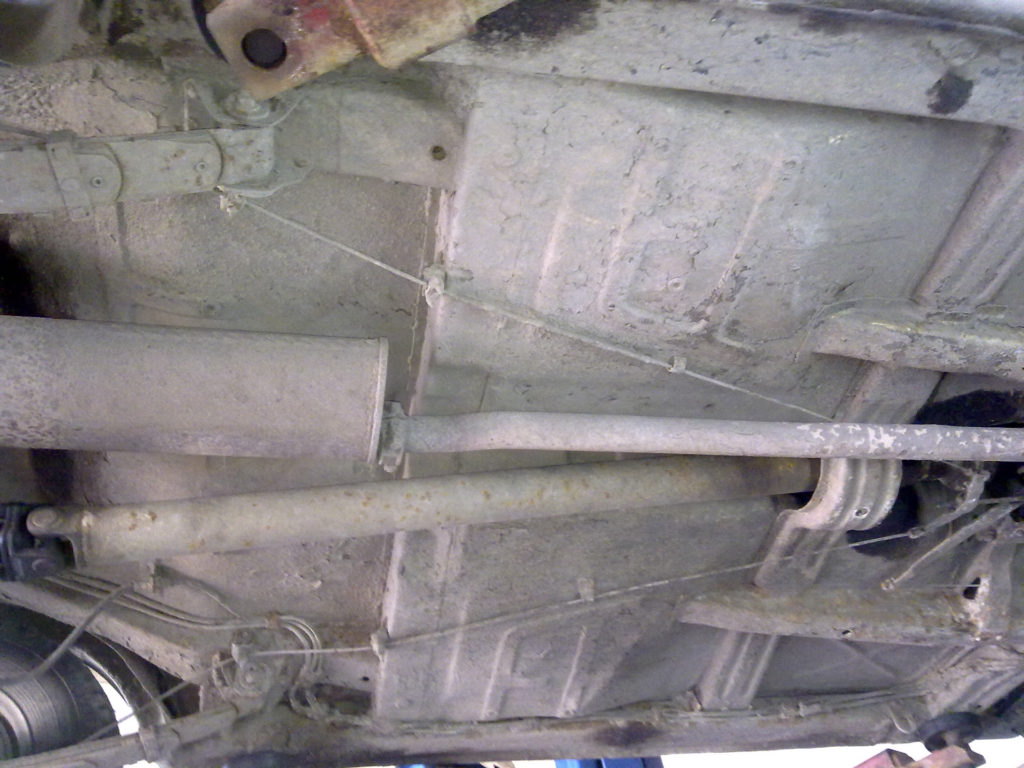

On a car that looks mostly rust free from outside, the main areas to look for are on the underbody (front and rear subframe rails, body sills and torque boxes, foot wells, trunk floor). Metal on these parts is thick (~2 mm on load bearing parts) and often it is just relatively harmless surface rust that can be removed by sand blasting. However, collection of water inside the inner cavities can lead to even thick metal rusting through.

Repairing these areas is usually quite simple and straightforward – except for the rear subframe rails and trunk floor which have a complicated shape and many elements attached to them, such as leaf spring brackets (ideally, you’ll have to find original repair panels, which is getting difficult – or better yet, just avoid any cars with significant rust in this area).

However, serious rust on outer rocker panels, front and rear valance panels, cowl area, trunk seal lip, lower portions of doors and quarter panels, wheel arches, windshield and rear window channels or top surfaces of front fenders (if no fender liners were installed, or water collected in the cavities above fender liners) is not unheard of either.

Rust on lower portions of the outer body panels is often caused by “sandblasting” and paint being chipped away by flying gravel and other road debris. Such rust is often superficial and usually doesn’t eat all the way through the sheet metal. This kind of damage is typical for cars that spent most of their life in rural areas with prevailing gravel and dirt roads, and it is relatively easy to repair. However, if neglected, it also can turn into some very nasty rust-through.

Much more severe rust in the same areas is caused by long-term storage of the car in a damp garage with no proper ventilation, as well as collection of moist dirt. In this case body panels would rust inside out, and any visible rust would be a rust-though.

Rust holes in the cowl area, on the windshield channel, or in general anywhere above belt line, may be a sign that the whole car is probably a rust bucket.

Worst case scenario is when rust is camouflaged with liberal amounts of body filler (can be detected by a coating thickness gauge).

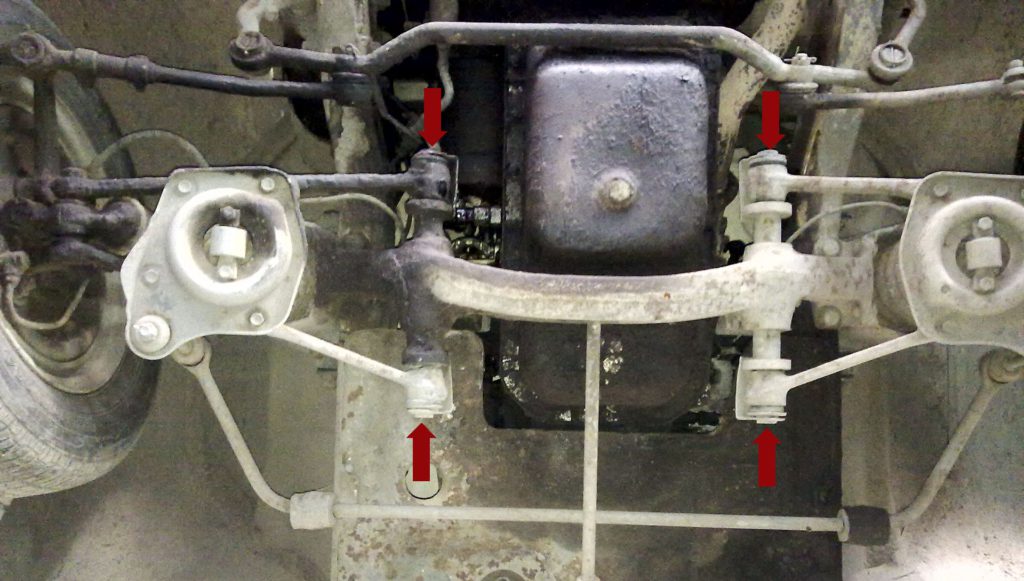

There are four rubber drain plugs on the body sills (larger arrows), and also several elongated slots in the rocker panels (smaller arrows). Carefully remove (or ask the owner to remove) the plugs and check the slots – that is part of the regular maintenance procedure. Everything should be dry, or – even better – filled with something oily (not watery). Quite often the slots are clogged up and/or deformed, and the plugs haven’t been touched for ages. If water is sloshing around in the sills when you’re rocking the car, it is a very, VERY bad sign.

Body sills and outer rocker panels on these cars also often suffer from improper jacking or hitting uneven ground (by the way, try not to jack up the car by the rocker panels if possible – use front suspension crossmember or spring plates on lower A-arms, front eyes of the leaf springs, bolt plates or rear axle). Such bends are not a purely cosmetic problem as they often cause rust if neglected. If it’s not yet the case, such damage can usually be fixed with a tack welder and a slide hammer.

Avoid cars with replaced body panels (typically front fenders, front and rear valance panels, rocker panels). Repair body panels are usually of inferior quality.

Original rocker panels have six small holes that are used for mounting rocker panel moldings (and two more holes are on the front fenders). Moldings were often removed and holes plugged to prevent corrosion. No holes (or even traces thereof) usually means replaced rocker panels. Not a good sign by any means (look for welding seams on the underbody). No holes on the fenders usually means replaced fenders.

Avoid freshly resprayed cars, unless it was a complete professional restoration by a reputable restorer / restoration shop, and the seller can prove that (photos, receipts, etc.). Ideally, the car should have original paint (which most likely will be faded and blemished) that only needs local repairs.

A roof rack is usually a sign that the car was used to carry a lot of stuff. GAZ-24’s roof pillars generally are not prone to fatigue cracking, as, say, GAZ-21’s A-pillars, but be careful nonetheless.

Fit and finish was never perfect on these cars (sometimes you can see that body panels are not perfectly lined up even on factory publicity photos), however uneven and/or overly wide (or too narrow) gaps are most likely a sign of body repairs – just don’t get too picky. What you want to look for is consistency. If some panel gap doesn’t look right to you, compare it to the other side – the gaps should be more or less the same on both sides.

Again, we’ll use this beige car as an example. My educated guess would be that both front fenders on the car probably have been replaced, either due to collision damage, or (more likely) simply rust. Note the suspicious gap between driver’s door and left front fender. This gap stands out as too small compared to the rest, probably the door even scratched the paint on the fender when opened, and the fender is also not flush with the other panels:

Even considering that the fender has holes for the rocker panel molding, it seems that it’s been replaced at some point. Could be sloppy manufacturing as well, but the other gaps seem to be okay(ish) and this one just stands out, so this version is less likely. Let’s check the other side:

The panels are not perfectly lined up either (not unheard of on the later cars; this one was built in 1983 and quality control was not what is used to be during 1970s), however the gaps look more or less consistent. However, I’d bet that both fenders are replacement parts, and the right one is just better lined up (still not good enough). Checking the fender mounting bolts for scratched paint may give your some more insight.

The “Volga” script is also missing on both fenders in this example, but such ornaments that collect water and provoke rust were often removed by the owners, so it is not a definitive sign of body repair.

In any case, making this car look good would require some bodywork (not to mention a complete respray). However, it is still a relatively good start.

Also, note how badly bent both rocker panels are. One of the major bends on the right one is, unfortunately, my fault… Usually such damage can be repaired with a reverse hammer (dent puller), however properly restoring the factory look may require some skill, because the rocker panels have a rather complicated cross-section.

Another common problem is doors not closing properly, requiring a forceful slam to fully shut. There are several possible causes:

- The doors and/or door locks may be out of alignment, so the lock mechanism is not properly lining up with the striker on the door frame;

- The doors just sagged and are hanging too low because the hinge pins and bushings are worn (would also cause the above mentioned problem);

- Third, and the worst possibility – the whole body is deformed because of accident damage or welding gone wrong.

Open the door that doesn’t want to shut, grab it by the window frame and try to lift it. If there is noticeable play in the hinges, worn hinges are the most likely cause. Hinges are bolted on, so it’s a relatively easy fix. Replacement hinges are available, and the original hinges can be refurbished by installing new pins and bronze bushings (blueprint).

Usually the driver’s door sags the most, and rear doors close just like on a new car. If the whole body is deformed, on the other hand – all doors won’t shut properly.

Transmission

If the original clutch works fine, chances are high it will continue to. Hydraulic linkage should be rebuilt in any case.

Typical problems of the gearbox are:

- Hard and/or noisy gear shifting, or gears not shifting at all (usually either worn out clutch disk, or worn synchromesh blocker rings; but first of all – check the hydraulic linkage for fluid level and air in the system);

- Popping out of gears under load (wear of the gears and/or bearings).

- Extensive front-to-back play of the gear shift lever in neutral and in gears (worn linkage inside the gearbox – not a critical problem by itself, but difficult to fix, and also a telltale sign of a worn out ‘box);

- Broken springs that return the lever into neutral position (easy to replace);

In some of these cases, complete overhaul is required (it’s complicated and some parts are difficult to get because the 4-speed transmission is out of production for several decades).

Worn out rear axle works with a prominent howling at high speeds (over 60…70 km/h). If it doesn’t howl, chances are high that nothing bad is going to happen to it any time soon (still, changing oil in the differential housing, repacking / replacing the bearings and replacing the seals is in order).

Suspension

The front suspension is probably the single most problematic mechanical element of the whole car. The first telltale sign of trouble is that the front wheels have a noticeable negative camber (top end of a wheel is pointed in towards the center of the car) and the tires have an uneven wear pattern. That means that the kingpins, the hub bearings, the bushings, the trunnions or, most likely, all of the aforementioned parts are worn out, and the front end overhaul time is near. And it’s nothing like rebuilding your everyday car’s or truck’s ball joint suspension, trust me.

Expect most of the nuts, bolts and other fasteners to be stuck, and the only way to loosen them may be to heat them with an Oxy Acetylene torch. Lower A-arm pivot bolts are especially prone to this:

In the worst-case scenario, the pivot bolts just snap when you resort to you old trusty one-meter long breaker bar to unscrew them, or the thread inside the suspension crossmember is terminally damaged. There are ways to deal with this predicament, but I won’t scare you just yet (hint: it involves a lot of heating and hammering).

Rebuild kits for the front suspension are available, but the quality of most modern replacement parts is very low. Most knowledgeable owners would try to find Soviet-made NOS parts (except for the rubber which is just too old to function properly).

Rear suspension is for the most part indestructible, but the leaf springs are most likely sagged, some of the leafs may be cracked or even broken, and eye bushings and plastic spacers would have to be replaced. Additional leafs in the leaf springs are a sign of heavy loads the car used to be subjected to – assess the damage.

Steering

Look for excessive play in the steering. The steering box is durable and most likely would only need some adjustment, but the tie rod ends and the idler arm may need to be replaced, or at least refurbished by disassembling, cleaning, replacing the rubber parts and packing with grease. Tightening the bottom plugs of tie rod ends may eliminate the play for some time:

The amount of force required to turn the steering wheel should be constant for the whole travel lock-to-lock, without any jamming (usually a sign of an irregular wear pattern and/or pitting on the worm gear inside the steering box).

Brakes

The whole system should be completely overhauled. Conversion to DOT 3 / 4 break fluid is advised (DOT 5 may also be a good option, but very few people actually tried it out, so I’m not sure if it should be recommended or not).

The Volga’s drum brakes are similar to the Lockheed brakes that were used, for example, in Chrysler Corporation cars until probably 1960s. It is an old-fashioned and frankly quite odd design from the modern point of view. The break shoes pivot on eccentric anchor bolts and require adjustment each time they are replaced. Adjustment procedure is similar to the Lockheed brakes and most likely can be done using the same tools (there’s a metric ton of information on this subject on the Internet; you may want to start with this article). In practice, it was most often done “by feel”, and improper adjustment of the brake shoes is one of the reasons why a lot of people complain about poor performance of the Volga’s brakes.

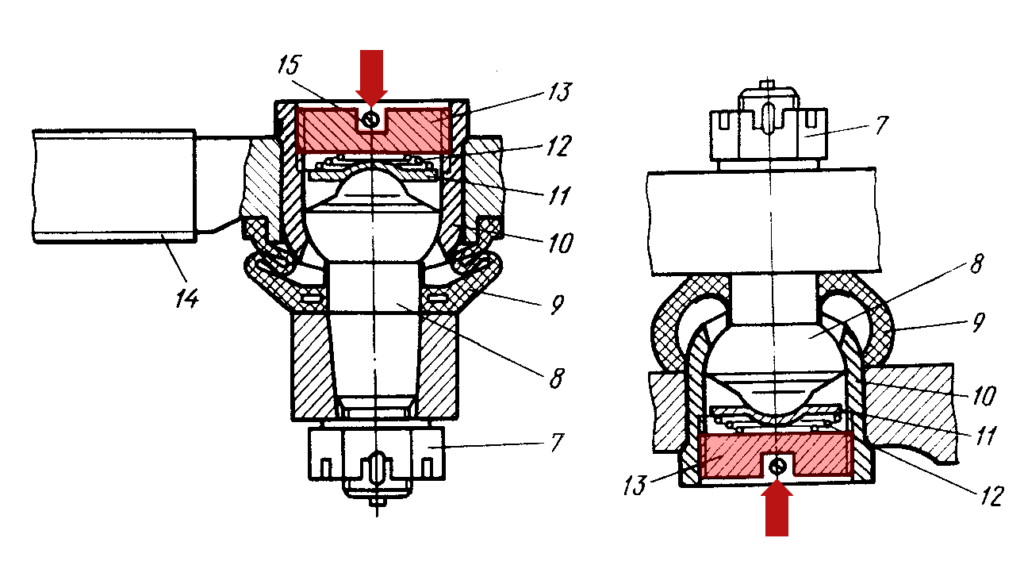

Except for that, the brakes are completely self-adjusting and do not need any adjustments between shoe replacement (the proper gap between the shoes and the drum is maintained automatically by a clever mechanism that is hidden inside the slave cylinders).

Engine

The engine is very reliable and robust if properly assembled. However, that is a problem by itself, because a lot of owners subjected the engine to such a huge amount of abuse that it could barely cope with it. As the result, many cars have engines in very poor shape (but they still start, run and drive).

On of the major source of problems with these engines is the use of cheap mineral oil by a lot of owners. These engines can run happily on almost anything oily, but, combined with overly long intervals between oil changes, in the long run that leads to buildup of sludge and deposits everywhere in the engine, clogging the inside of the crankshaft and other oil channels and leading to oil starvation and/or oil pressure problems.

Another problem is continuous overheating, as aluminum blocks and heads are very prone to thermal warping. Overheating, in its turn, is typically a consequence of the use of tap water as coolant agent in the old days, leading to corrosion and collection of scum, rust and scale in the cooling system, which drastically reduces its efficiency. It is much more dangerous if the engine constantly “runs hot” than if it is subjected to severe, but short-term overheating.

These engines usually wear more or less as a whole, they do not have any major parts that are specifically susceptible to wear or need periodic replacement. The camshaft is driven by a pair of timing gears, which normally last the whole engine life – there is no timing belt or chain to replace. In most GAZ-24 engines the valves do not have positive stem seals and use umbrella style seals instead, which are suspended on the valve stem and do not wear mechanically (the rubber still tends to disintegrate over time, but quality made parts can last for many years or even decades).

Look for the typical telltale signs of wear (blue exhaust smoke, knocking, etc.). Compression tester may give you some additional info. A worn engine may yet run for quite some time, but get ready for an overhaul.

If the cooling fluid is rusty colored and murky, corrosion is running amok in the cooling system and a lot of damage to the inside of the cylinder block and head is to be expected (may be irreparable if the corrosion has already “eaten away” enough of the aluminum).

It’s okay if the engine is leaking some oil (all old Volga engines have minor and/or major oil leakages, most typically from the rear main seal, but also in other areas; all of them can be fixed, though).

Another common problem is low oil pressure (it is acceptable if the control lamp flashes at idle, but it must go off as soon as you rev the engine).

Early cars had simple and relatively reliable Lenkarz K-126G 2-barrel carburetors. The only serious problem you may encounter with them, other than lack of proper tuning and simple mechanical wear, is a leaky float valve (which uses a fluoro rubber O-ring as seal, similar to old Ural motorcycle carbs, which degrades over time); it can be replaced with a modern one with a rubber-nosed needle, which is 100% reliable (p/n UNIKAR7). Most other problems are usually connected with mechanical wear or air leaks caused by deformed flanges and bad gaskets.

Some of the later cars (after 1985) got a more modern, but also more problematic, Lenkarz K-151 carburetor, also with 2 barrels, but designed for better fuel efficiency and lower emissions. Fortunately, it never achieved the complexity of the more advanced emission control systems used in the Western countries at the time, but still has its own share of problems, most of which are rooted in poor manufacturing tolerances and generally sub-par design and quality of many of its parts. In most cases, all of its pneumatic and electrical subsystems would be deactivated by previous owners. K-151S is a later, improved and more reliable, version. Some of the late cars (usually with low-compression engines) still had improved K-126GM carbs based on the older design.

Also, early cars were equipped with a purely mechanical point-type ignition system, which is dead-simple, but needs a lot of maintenance to work reliably and provide acceptable performance, including periodic dwell angle and timing advance adjustments. If not properly maintained, it is the primary source of any and all headaches you’ll have with these engines.

1985 and later cars use a point-less electronic ignition, which doesn’t require much periodic maintenance, but the electronic components are not supremely reliable (having a spare ignition module is essentially a must, p/n 131.3734).

If the car won’t start and the engine is seized (crankshaft won’t turn by hand) – usually an engine rebuild is in order.

Interior and trim

Usually, it is a good idea to buy a car that is as complete and original as possible, even if it has some amount of rust damage and/or mechanical problems. Some exterior and interior trim pieces are hard to find and/or expensive – rocker panel moldings, for instance. Especially so is the unique trim that was used only on early cars (pre-1972 all-plastic turn signals, early side rear view mirrors, etc.). Reproductions of some of these parts are available, but unfortunately not all of them.

In general, interiors of these cars (especially the early ones) are very simple, with few plastic parts that can degrade over time, and can be restored to “like new” condition without much trouble. Most of the weatherstripping and quality reproductions of some plastic parts and original styles of upholstery are readily available via classic car parts dealers today.